- North America:(408) 850-9978

- International:+44 1428 741756

Electrostatic Discharge (ESD) presents a critical and underestimated threat for manufacturing engineers and professionals in microelectronics production.

Article

ISO, or the International Organization for Standardization, sets global standards for quality assurance, including management, testing, and calibration. Industry experts develop their standards and serve as guidelines for companies worldwide.

Guide

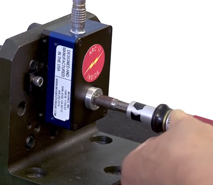

In manufacturing and assembly, the smallest details can have the biggest impact, especially when working with sensitive electronic components. ESD-safe torque screwdrivers provide a reliable solution to protect components and ensure production quality.

Article

Eliminating fastening errors hinges on employing proper techniques and tools. It is imperative to recognize that a process is considered under control until variances from the expected results are detected, prompting the need for an audit discussion. Contrary to assuming a lack of auditing, it is, in fact, essential.

Article

-1.png)

Torque measurement serves a crucial role in three key phases of the assembly process. The imperative control of torque is vital for companies striving to uphold the integrity of their products, guaranteeing quality, safety, and reliability without compromise.

Article

.png)

When devising a production area, investing time in planning the ergonomics of the operation and seeking advice from health and safety inspectors or ergonomic managers can yield substantial long-term benefits. Ensuring that both the workplace and the assembly operation align with the needs of the majority of operators.

Article

Every day, fasteners play a crucial role in securing components across various manufactured products, from electronics and medical devices to automobiles and aircraft. However, one critical aspect often overlooked is whether these fasteners comply with RoHS standards.

Article

.png)

Selecting the right power tool for your application is crucial to ensure the required torque accuracy. Factors such as joint stiffness and the nature of the joint play a significant role in determining the appropriate tool.

Article

.png)

Ensuring the secure and accurate tightening of bolted joints is paramount to the structural integrity and overall performance of various assemblies. To delve further into the guidelines for effective tightening, let's elaborate on each key point.

Article

.png)

In the realm of fastened joints, joint relaxation is an inherent phenomenon influenced by factors such as material embedding and the compression of "soft parts" like gaskets or plastics under clamping forces during torque fastening. While well-designed joints may experience negligible relaxation, it becomes a significant concern in applications involving gaskets, spring washers, or plastics.

Article

-1.png)

Efficient torque management in manufacturing and assembly processes is critical for ensuring production efficacy. The repercussions of improperly torqued fasteners, ranging from vibrational loosening to potential breakage, underscore the need for precise torque control.

Article

-1.png)

In the dynamic realm of manufacturing, the assessment and analysis of process capability and performance are crucial for ensuring quality standards. One key statistical measurement employed for this purpose is Cpk.

Article

Regardless of economic climate, the safety and well-being of manufacturing workers should never be compromised. Despite the challenges, it is the responsibility of manufacturers to prioritize the prevention of injuries and disorders caused by repetitive tasks and improper processes.

Article

.jpg)

In the intricate world of manufacturing and assembly, the precise tightening, control, and measurement of torque in fasteners play a critical role in ensuring production efficiency. A fastener that is inadequately torqued can lead to vibration or loosening, while excessive tension may result in snapping or stripping of threads.

Article

-1.jpg)

An impact wrench is a tool that utilizes a discontinuous drive clutch system and compressed air to generate torque. Widely used across various industries, these wrenches are commonly employed for tightening lug nuts during tire changes on automobiles.

Article

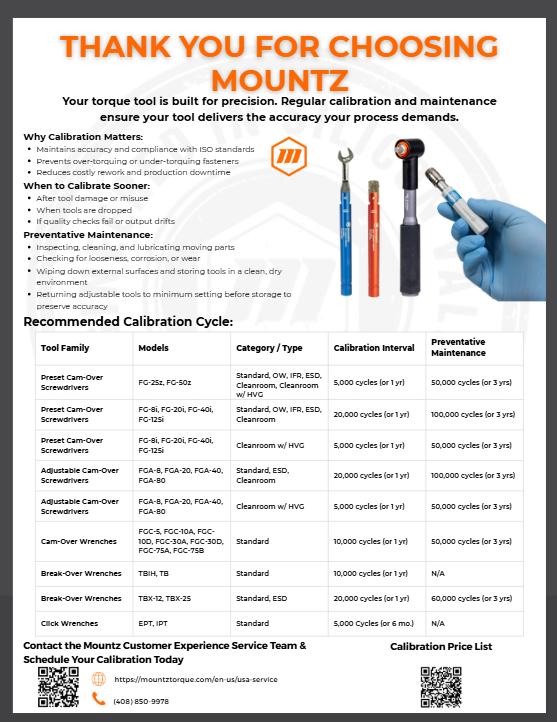

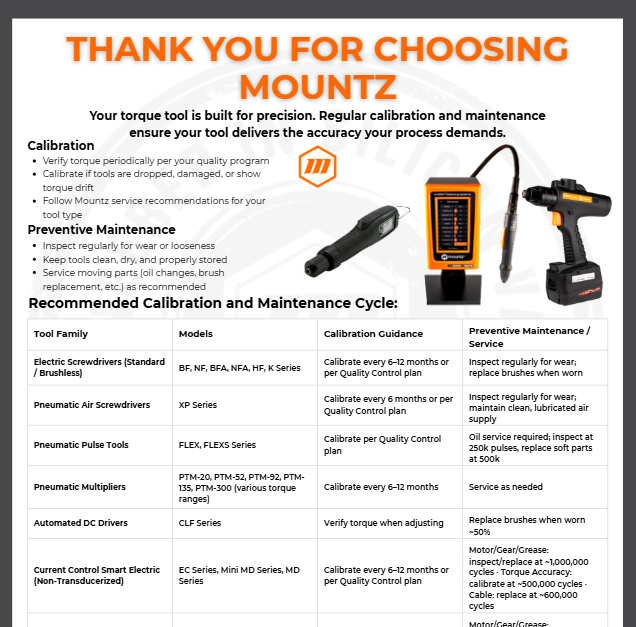

Regular calibration of torque tools is essential for ensuring consistent accuracy and adherence to international standards. By calibrating torque equipment regularly, organizations can ensure peak performance and identify potential tooling issues before they escalate due to wear or damage.

Article

In the realm of fastening, overcoming challenges involves controlling variables or eliminating potential causes that lead to undesired outcomes. Let's delve into everyday unwanted fastening events.

Article

Fixed assets like holding tanks, heat exchangers, and nuclear reactors play pivotal roles in numerous industries and public services. However, when these assets malfunction, the ensuing downtime can mean substantial costs for production facilities.

Article

For many manufacturers the production of goods often spans multiple countries and involves numerous smaller contract manufacturers. Regardless of the complexity of this network, the company that initiated and owns the design is responsible for the final product and must ensure its safety and effectiveness.

Article

Efficiency is the backbone of any successful business endeavor. The core of business operations lies in the ability to accomplish more tasks at a lower cost. In the manufacturing realm, the pursuit of efficiency drives companies to make decisions that maximize value.

Article

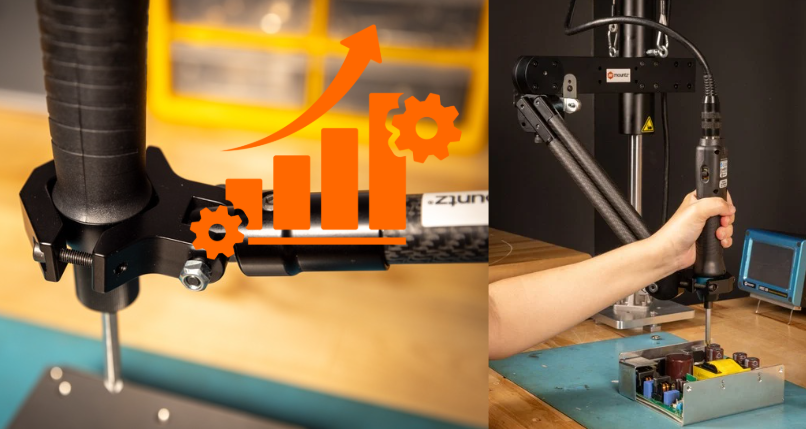

For assembly line managers and executives, the pursuit of enhanced production efficiency is an ongoing endeavor. This quest involves seeking cost-effective methods to boost speed while minimizing product losses. In the manufacturing realm, particularly with products secured by threaded fasteners, ample opportunity exists to optimize fastening systems for improved performance.

Article

Every manufacturing company should establish a robust quality management system (QMS), whether mandated by law or driven by common sense. Without such a system, even minor errors during production can snowball into significant issues once the product reaches the market. Whether the aim is to enhance safety standards, adhere to regulatory requirements, or minimize product loss, modern manufacturing demands a systematic approach to quality management.

Article

The assembly of flat-pack furniture, a hallmark of Scandinavian exports, offers insightful lessons regarding the significance of assembly line ergonomics. Although assembling such furniture might initially appear straightforward, employing power tools and basic accessories, the aftermath often entails physical discomforts such as hand strain from using screw guns, shoulder discomfort from tool handling, and backaches from prolonged bending.

Article

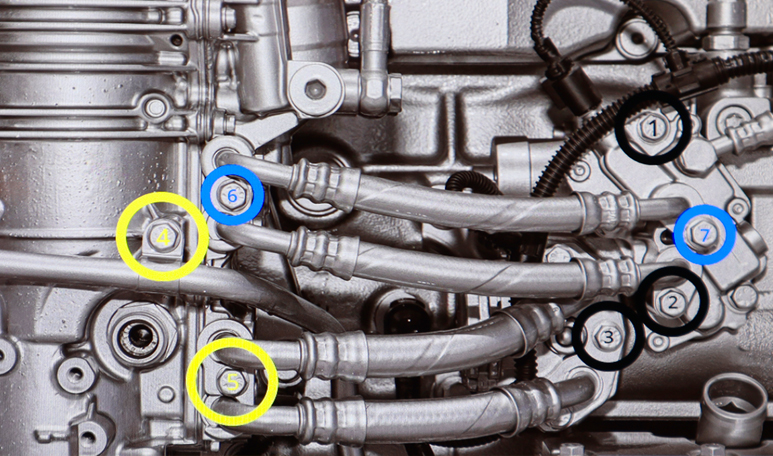

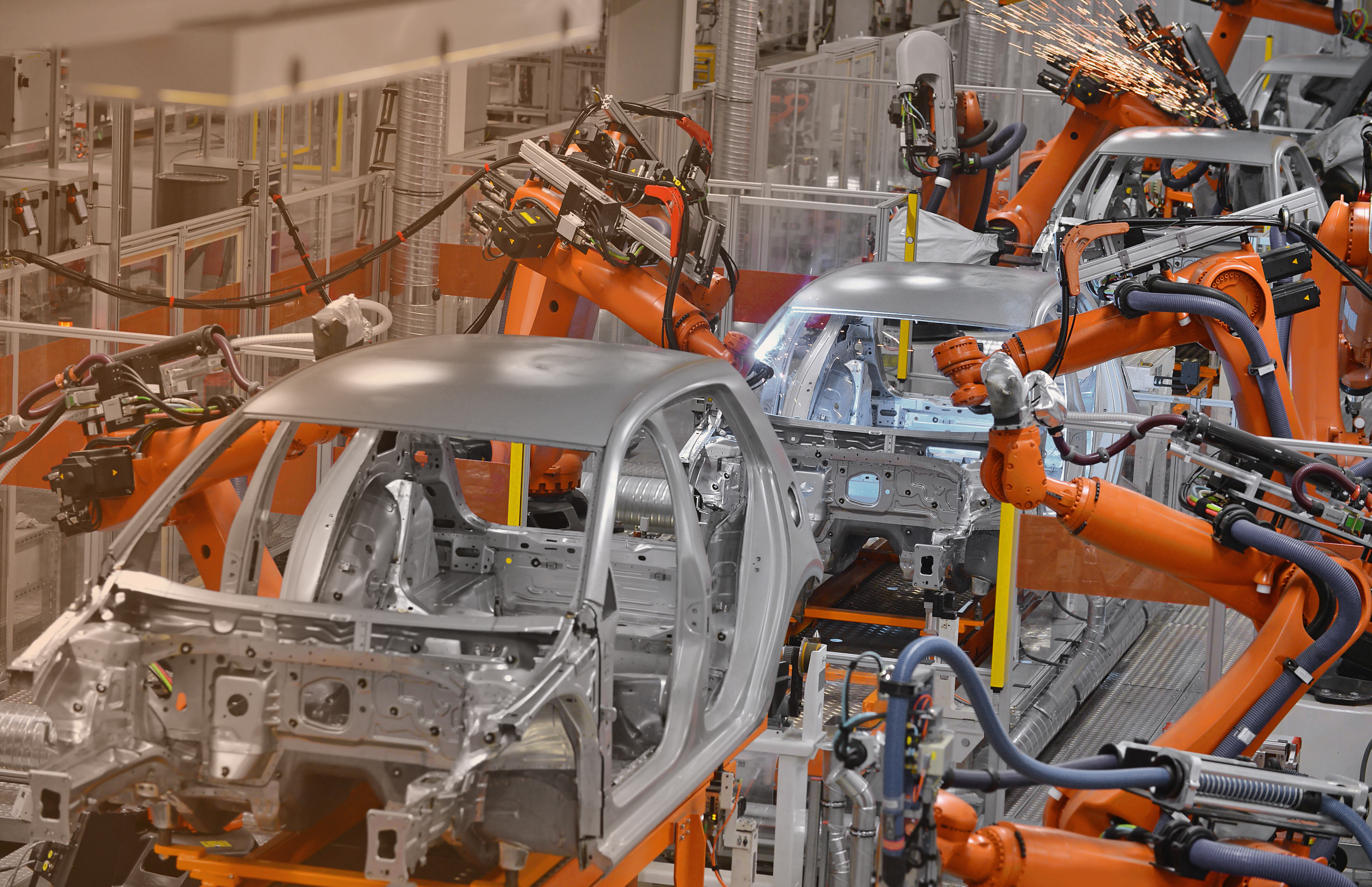

Precision is the cornerstone of automotive efficiency, reliability, and safety, whether in manufacturing or maintenance endeavors. Even compact automobiles represent substantial tonnage hurtling along roads at speeds surpassing those of the fastest animals. This dynamic generates considerable stress and vibration across all automotive components, particularly fasteners securing these vital parts.

Article

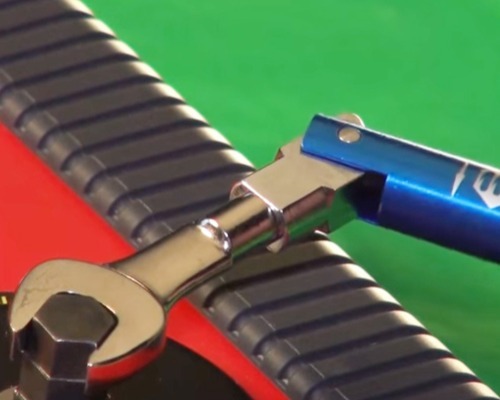

Car brake line maintenance often presents a familiar quandary: the imperative of establishing secure, leak-proof seals between fittings crucial for the brake system's integrity. These connections must withstand the rigors of daily driving, as any leakage compromising the line's integrity could precipitate brake failure—a safety hazard of grave concern.

Article

Meeting rigorous standards for product quality is imperative for manufacturing companies. Ensuring consistency across products assembled on production lines presents a challenge, particularly in fastening bolts to precise specifications—a task often beyond human capabilities without mechanical assistance.

Article

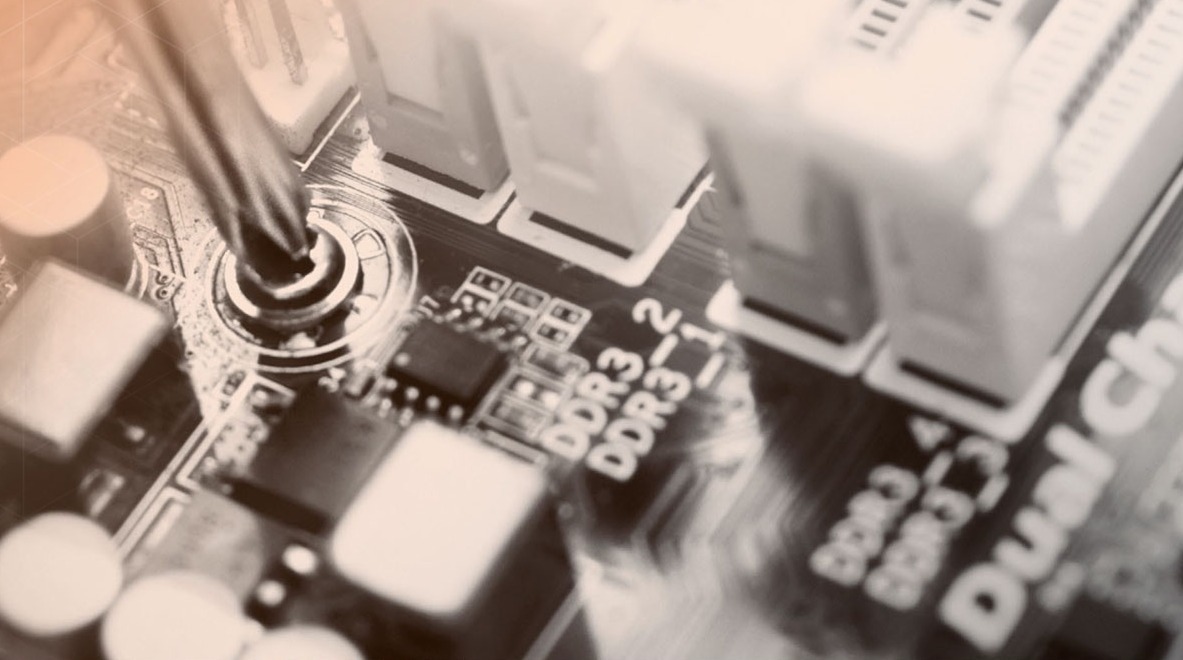

As we navigate the digital era, electronics have become integral to our daily lives. The proliferation of devices has surged the demand for high-quality electronic assemblies, necessitating global electronics contract manufacturers to cater to the unique requirements of various electronic assemblies.

Article

In the realm of manufacturing, precision holds paramount importance, particularly within the domain of medical devices. The efficacy of diagnostic tools hinges on the meticulous assembly of every fastener and joint, ensuring seamless transmission of signals devoid of interference and encountering precise resistance levels.

Article

In various industries, relying on sophisticated processes and quality control measures is crucial to meet the ever-evolving demands of contemporary markets. Whether the goal is to minimize scrap rates or mitigate potential liabilities, companies pursue the most effective tools for enhanced fastening techniques.

Article

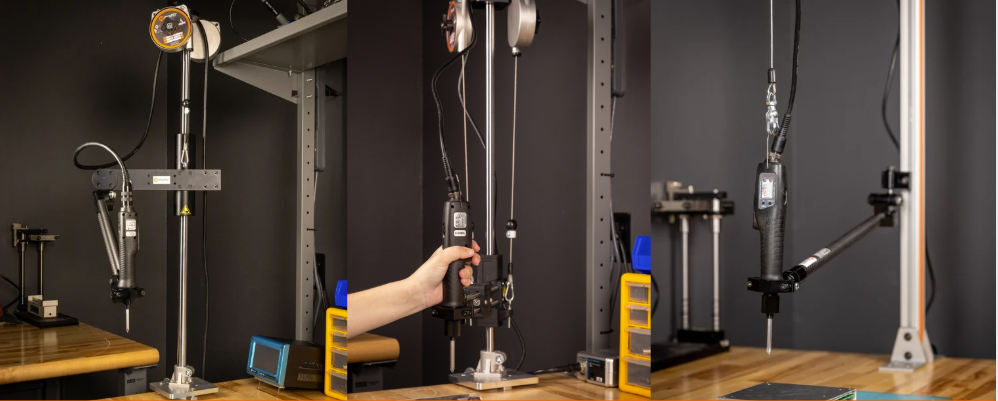

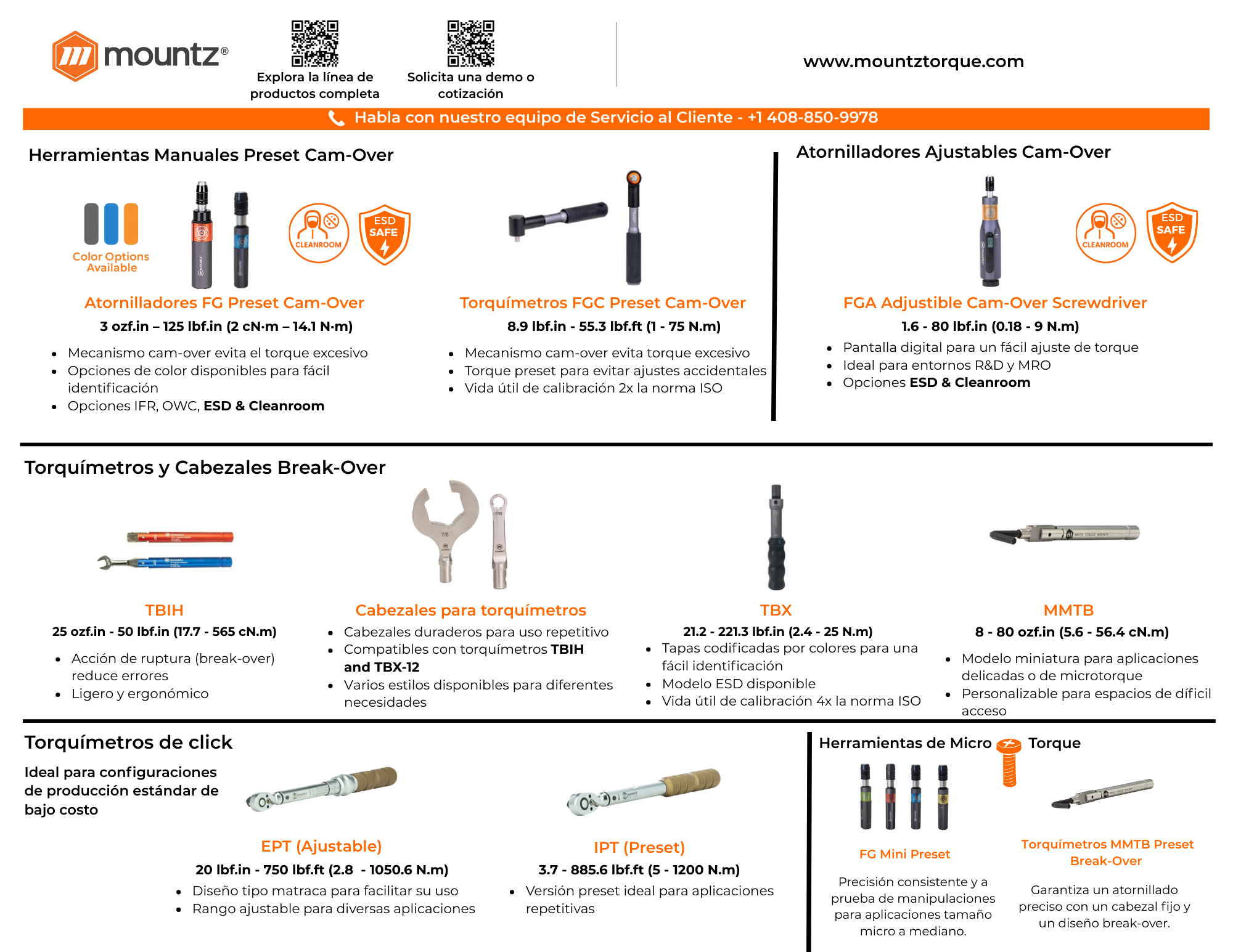

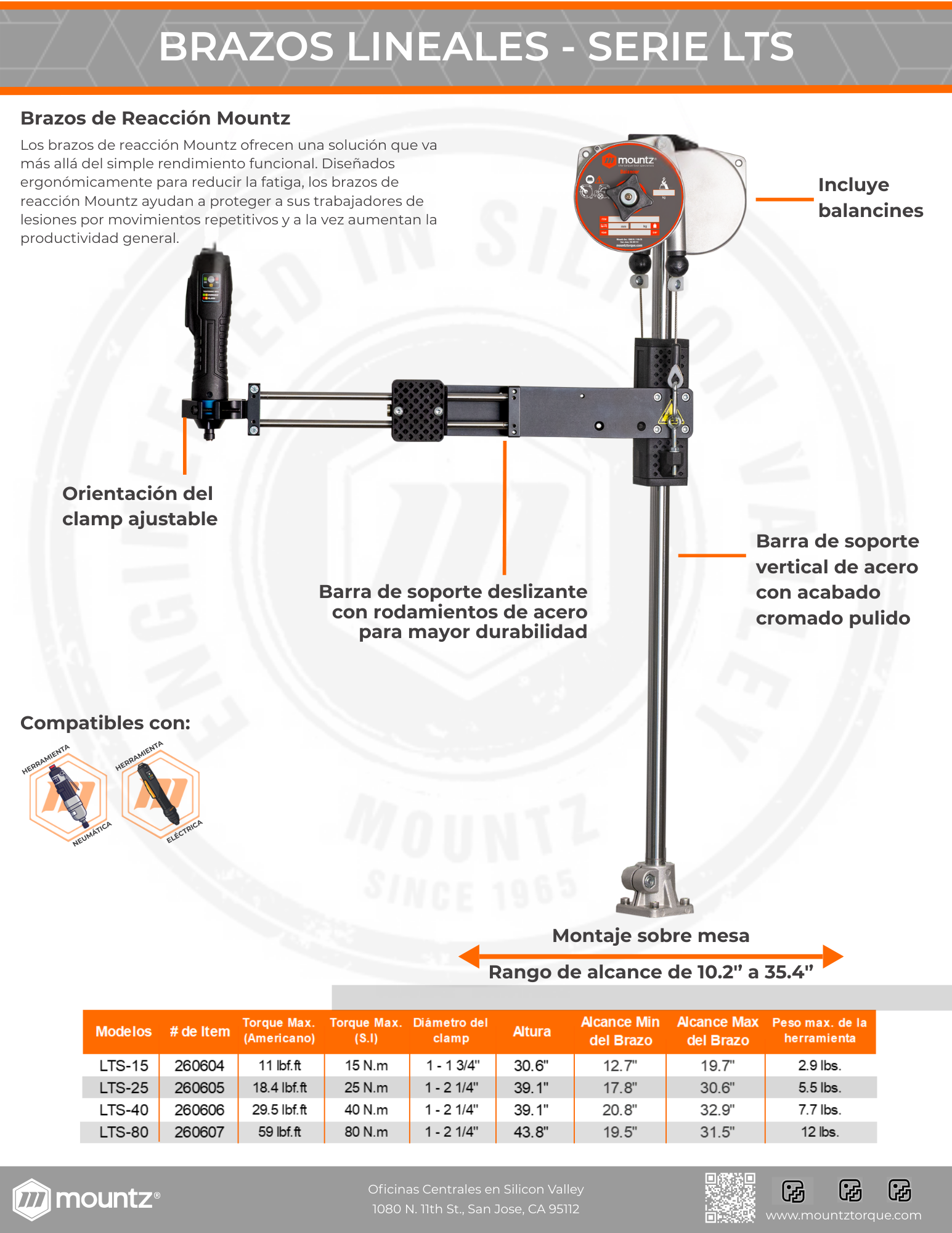

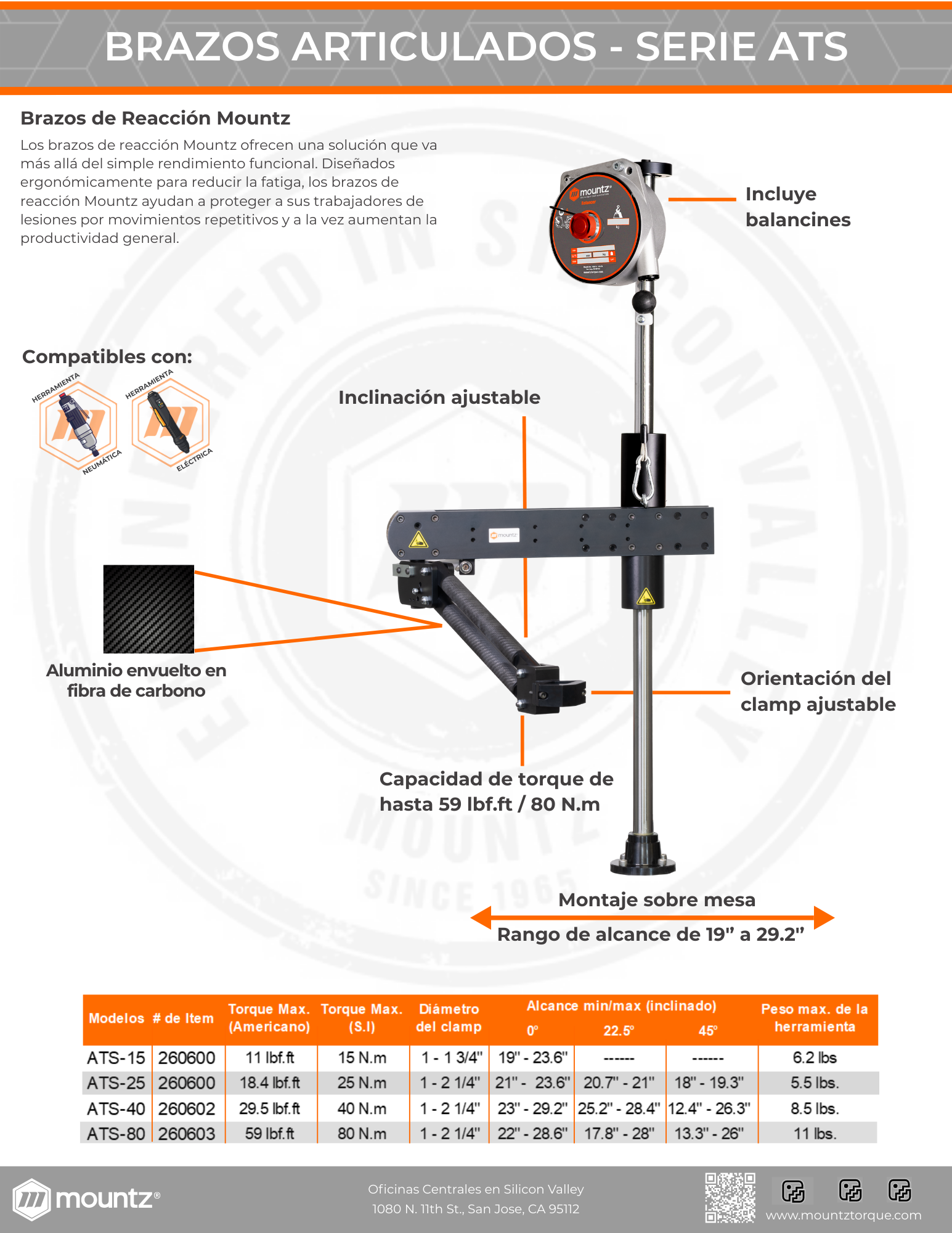

Selecting the right torque arm for your application involves thoroughly assessing specific requirements and constraints. Follow these steps to choose a torque arm with optimal performance and reliability.

Guide

In the world of torque screwdrivers, there are two main categories: "Preset" and "Adjustable." The choice between them depends on your specific needs and objectives.

Guide

In the intricate world of controlled environments, where precision and cleanliness are paramount, the choice of tools plays a pivotal role. Dust, microbes, volatile organic compounds (VOCs), and pollutants are adversaries that must be

meticulously managed in industries such as

semiconductors, medical devices, aerospace

and defense, and optics.

Whitepaper

In today's global manufacturing landscape, companies relying on fasteners, bolts, and nuts face a critical imperative: ensuring adherence to international standards like ISO in their torque processes and quality protocols.

Whitepaper

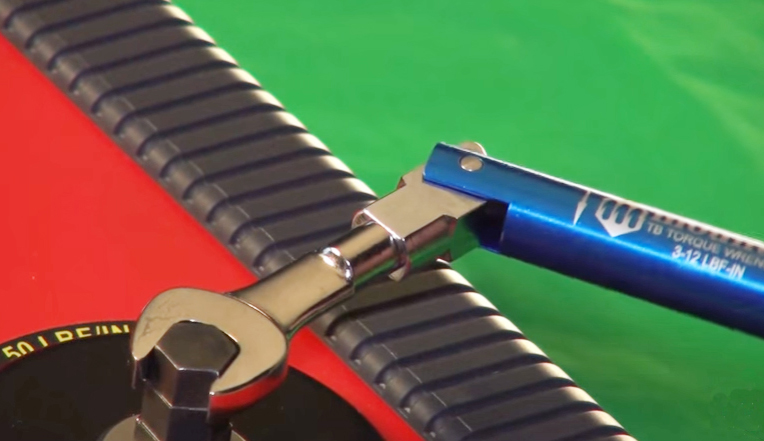

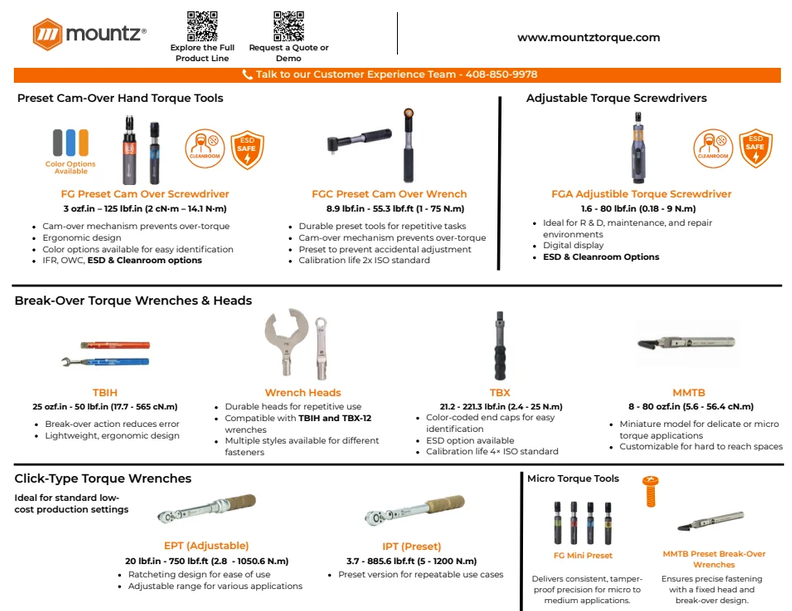

Torque wrenches incorporate limiting mechanisms essential for controlling the torque applied by an operator. This mechanism is pivotal in distinguishing between various torque wrench technologies.

Whitepaper

Repetitive motions on assembly lines pose a risk of repetitive stress injuries, potentially leading to workers' compensation claims. A practical solution to these issues is the torque arm.

Guide

Selecting the right torque arm for your application involves thoroughly assessing specific requirements and constraints. Follow these steps to choose a torque arm with optimal performance and reliability.

Guide

Calibration testing intervals play a critical role in maintaining torque tool accuracy. These tools will inevitably fall out of calibration with use—a natural consequence of their operation. However, failure to detect such deviations can result in the unwitting creation of defective products, leading to potential liabilities. Therefore, regular testing of torque tool calibration is essential.

Guide

Understanding the measurement of torque and angle is crucial as it influences how fasteners hold sophisticated mechanical devices together. Typically, engineers and assembly workers use torque tools equipped to measure angle to manage torque effectively.

Guide

A pulse tool combines the velocity of an impact wrench with the precision of a clutch-based shut-off tool. It features precision-engineered components within a sealed chamber filled with specially formulated hydraulic fluid. This tool operates when pulse blades, equipped with precision rollers, press the fluid within the rotating chamber, generating hydraulic pressure that in turn produces torque.

Guide

To ensure the proper and efficient operation of pneumatic assembly tools, maintaining a clean and dry air supply is paramount. Moisture and contaminants in the air can significantly impact the performance and lifespan of pneumatic tools. Therefore, it is essential to implement measures to remove such undesirable elements from the air supply.

Guide

Choosing the appropriate heavy torque tool is essential for the task at hand. When dealing with challenging nuts and bolts, particularly those that are corroded, the fundamental need for power is undeniable.

Guide

In the realm of mechanical fastening, achieving the correct level of torque is essential for ensuring the integrity and reliability of assemblies. Torque wrenches serve as indispensable tools for precisely applying torque to fasteners, preventing under- or over-tightening that could compromise the structural integrity of components.

Guide

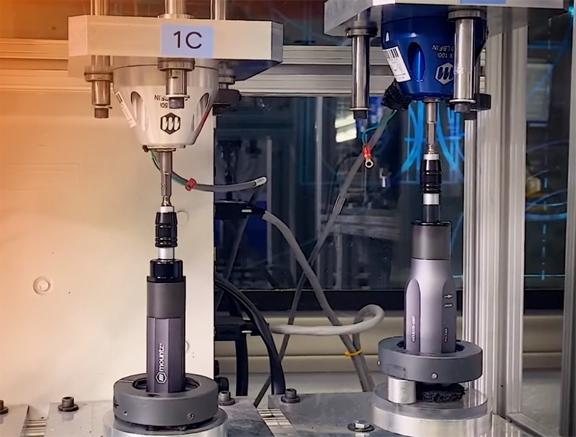

In today's industrial assembly operations, achieving precise torque application is not just a matter of accuracy but also a key driver of productivity. Consistency in torque control plays a pivotal role in minimizing production costs, warranty claims, and downtime on the assembly line. Let's delve deeper into some of the common challenges faced in industrial assembly and explore innovative solutions to address them effectively.

Guide

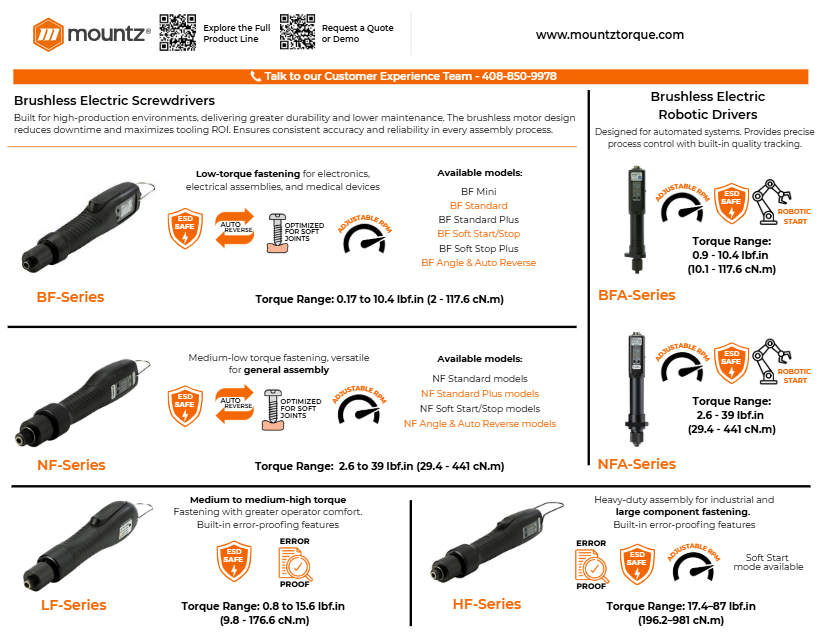

In high-volume production environments, the selection of electric screwdrivers is pivotal for ensuring seamless operations and maintaining product quality. Electric screwdrivers equipped with brushless motor designs offer numerous advantages over traditional models, contributing to enhanced efficiency, reduced maintenance costs, and improved overall reliability.

Guide

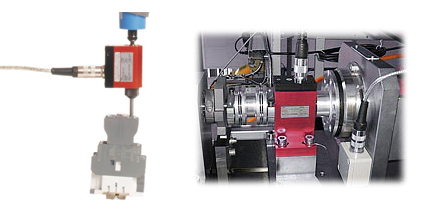

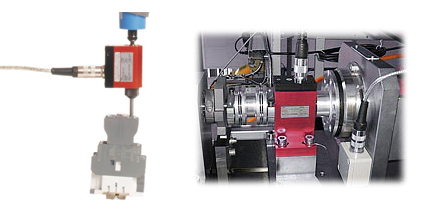

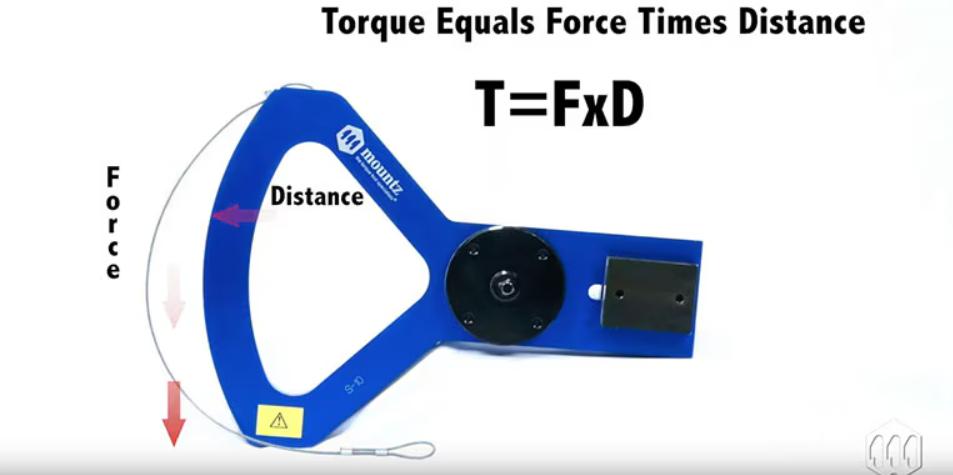

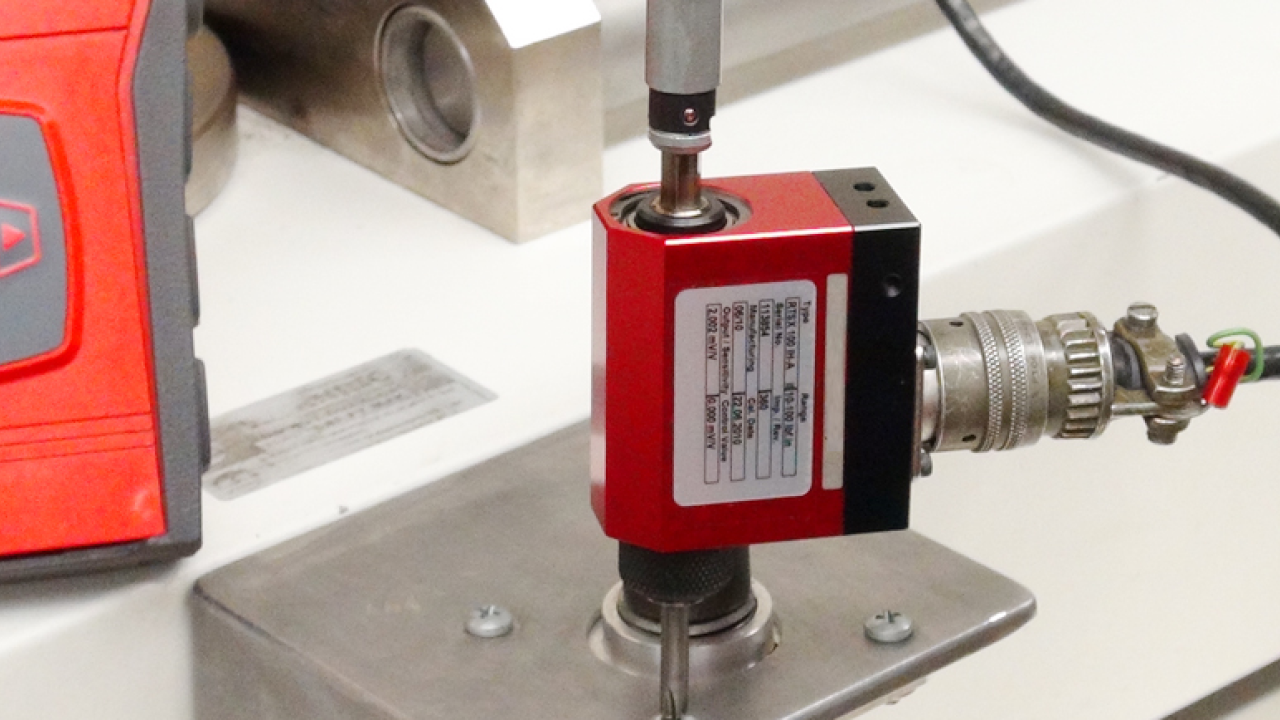

The accurate measurement of torque applied to rotating drives and fastening applications is an important criterion for evaluating production efficiency and quality assurance in manufacturing and assembly. There are many process monitoring applications that require rotary style torque sensors to be used to capture and record traceable measurement results.

Guide

When assembling parts with an electric torque screwdriver, numerous factors come into play to ensure precise torque control. Considerations include the hardness of the joint, the material used, and whether the screw is lubricated or treated with a locking patch. Surprisingly, one often-overlooked factor is the RPM setting of the tool.

Guide

Hand torque multipliers work by amplifying the force applied to a fastener. The torque multiplier fits over the fastener, with the torque wrench inserted into the multiplier, which then magnifies the wrench's torque output by a fixed ratio.

Guide

Tooling a factory is a delicate balancing act, especially when it involves assembling large volumes of products with small fasteners. Electric screwdrivers are the clear choice for such tasks, but selecting the right one can be overwhelming due to the multitude of options available.

Guide

When seeking tooling solutions, modern manufacturers must prioritize two key qualities: speed and precision. Both factors directly impact product volume, and consequently, profitability.

Guide

Electronics manufacturing and assembly present unique challenges that require specialized tools and techniques. The drive for miniaturization necessitates the use of small screws and delicate substrates, creating a need for precision and care in the manufacturing process.

Guide

Ensuring the consistent accuracy of torque wrenches requires periodic checks for wear or defective parts. Implementing a well-structured preventive maintenance program enhances tool performance and minimizes unexpected downtime, ultimately saving both time and money.

Guide

In 1999, a navigation error led to the tragic loss of the Mars Climate Orbiter, a stark reminder of the consequences of unit conversion mistakes. Despite its sophisticated design, the spacecraft burned up in the Martian atmosphere because course information was not converted from English units to metric. This event underscores the importance of understanding torque values, especially when dealing with metric and standard bolts.

Guide

In complex fastening operations with numerous screws and rapid production lines, missed screws can compromise product quality. Implementing batch counting and line control functionality helps ensure accuracy right from the start.

Guide

Many joints incorporate multiple fasteners, presenting a challenge in achieving proper torque, especially when joining non-flat surfaces. The sequence of tightening these fasteners significantly impacts the resulting preload and clamping force, crucial for holding parts together.

Guide

.jpg)

Our whitepaper delves into the nuanced intricacies surrounding the click-wrench mechanism's susceptibility to torque failures, juxtaposed with the protective capabilities of the cam-over-wrench mechanism in averting fastening failures and over-torque occurrences.

Whitepaper

In today's global manufacturing landscape, companies relying on fasteners, bolts, and nuts face a critical imperative: ensuring adherence to international standards like ISO in their torque processes and quality protocols.

Whitepaper

In today's smarter manufacturing environments, precision is paramount. As companies strive for higher-quality assembly processes, their tools must meet rigorous standards. This white paper explores the significance of Cmk in evaluating torque tools, using our latest line of preset precision screwdrivers as a case study.

Whitepaper

Tightening, controlling, or measuring the torque of fasteners lies at the heart of maintenance and manufacturing operations. The precise application of torque is not merely a matter of efficiency but a crucial determinant of product reliability and safety. This white paper elucidates the significance of treating torque wrenches as precision instruments, emphasizing proper calibration and maintenance.

Whitepaper

In manufacturing, torque often shrouds itself in mystery, confounding even seasoned professionals. Mastering torque control is indispensable for ensuring product quality, reliability, and safety despite its elusive nature. This whitepaper unravels the enigma of torque, elucidating its fundamental principles and highlighting its profound impact on bottom-line considerations.

Whitepaper

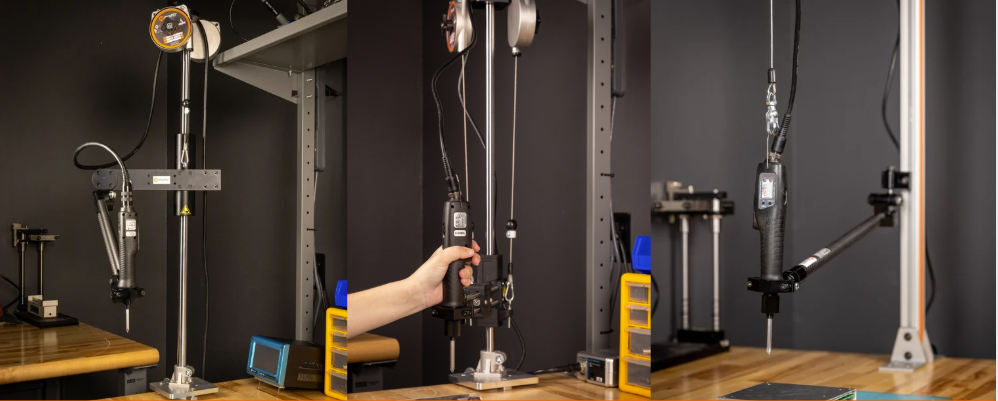

Mountz Torque was approached by a loyal Aerospace client seeking to enhance their productivity. The aerospace company employed light assembly electric torque screwdrivers in its assembly operation to construct power modules situated beneath the middle seat in each plane row, facilitating passenger device charging. Read our case study to learn how this manufacturer used Mountz tools to increase production efficiency.

Case Study

Bergstrom is a global leader in crafting climate control solutions for the commercial vehicle sector. Specializing in designing and producing cab climate systems for a wide array of automotive vehicles, commercial trucks, off-highway machines, military vehicles, and specialized transports, Bergstrom stands at the forefront of thermal management technology.

Case Study

Bergstrom is a global leader in crafting climate control solutions for the commercial vehicle sector. Specializing in designing and producing cab climate systems for a wide array of automotive vehicles, commercial trucks, off-highway machines, military vehicles, and specialized transports, Bergstrom stands at the forefront of thermal management technology.

Case Study

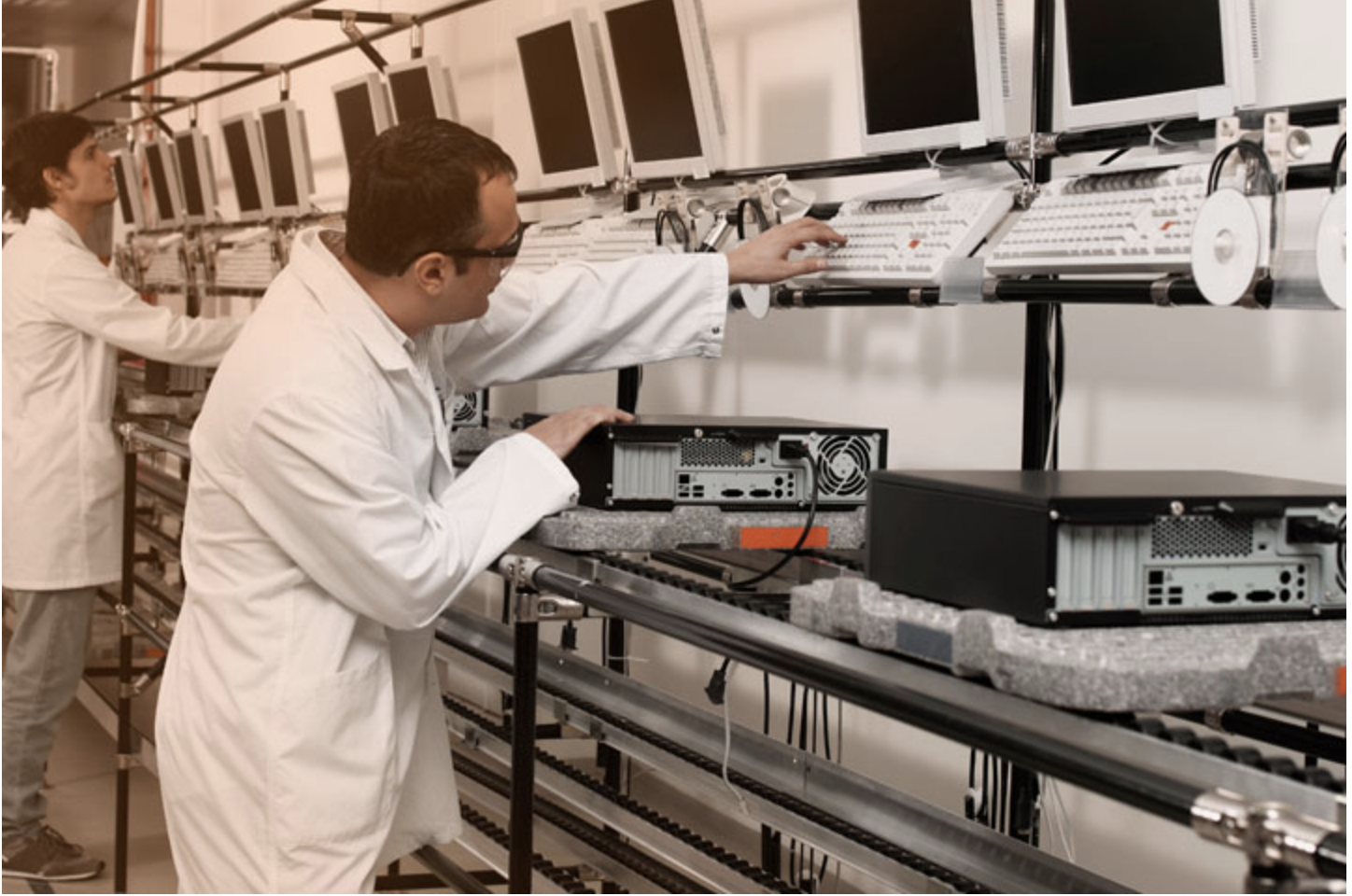

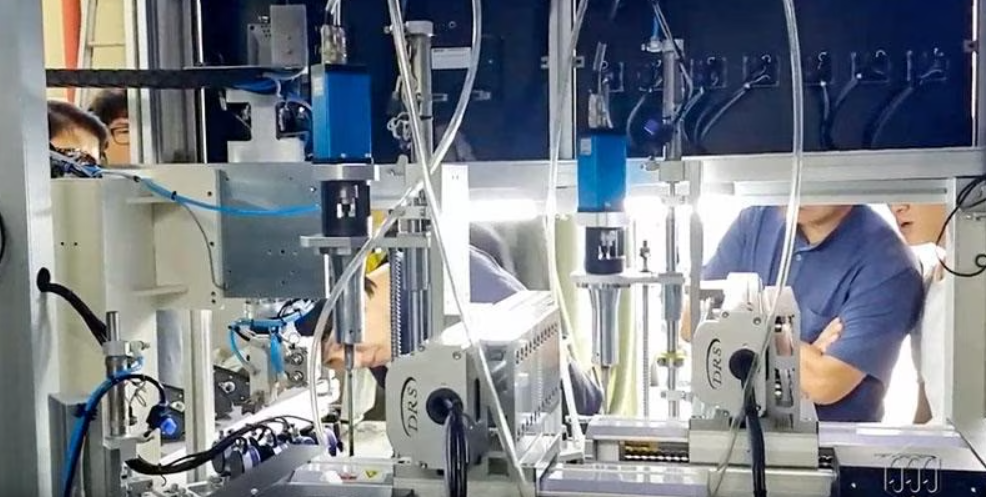

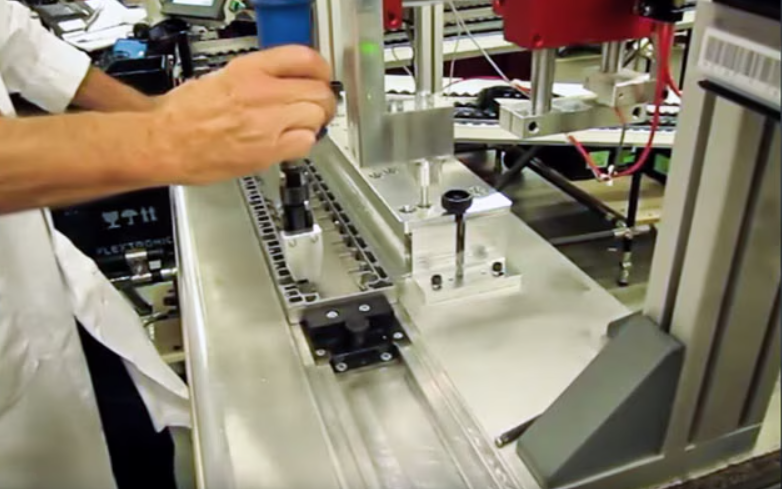

As we move deeper into the digital era, the demand for electronic assembly continues to soar. This international electronic contract manufacturer operates globally, tailoring its facilities to cater to the diverse requirements of various assembly tasks. Read the case study to learn more.

Case Study

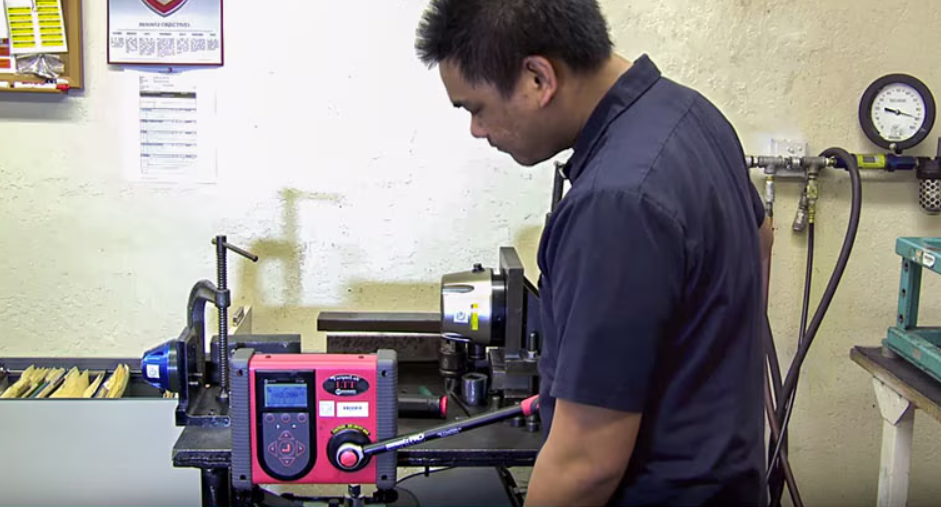

When torque tools slip out of calibration, miscalibration impacts product quality. Having an accurate way to regularly test calibration onsite is a great way to reduce risk and ensure safety. With Mountz torque analyzers and sensors, you can test tools before they go into service daily. Testing prevents employees from working with miscalibrated tools and enhances quality management. Using your own torque testing equipment is also more efficient since you can evaluate your tools without sending them to a laboratory. Whether you want stand-alone sensors for hand and power torque tools or run-down adapters that simulate actual joint conditions, Mountz has many options to choose from.

Digital Torque Catalogs

From better product quality to a lower total cost of ownership to guaranteed regulatory compliance, you can have it all with market-leading Mountz torque screwdrivers and wrenches. Built-in error proofing mechanisms prevent over and under-torque conditions so you can count on the quality of your work. Assembly and repairs performed with Mountz torque products allow any user to deliver precision torque control with confidence regardless of task and operator skill level. And when it's time for compliance inspections or audits, equipment calibration records provide clear documentation.

Digital Torque Catalogs

In order to keep up with modern production demands, you need tools that are faster, smarter, more accurate, and more powerful than ever before. Mountz answers that demand from the heart of Silicon Valley with a full line of innovative electric and pneumatic power tools and automation systems. With intuitive Mountz tool controllers, complex multi-pass assemblies become simple and your production speed will skyrocket. Quality control and regulatory compliance can be streamlined with real-time error proofing and time stamped documentation. From the simplest repairs to the most technical manufacturing projects and everything in between, Mountz power tools stand out from the crowd.

Digital Torque Catalogs

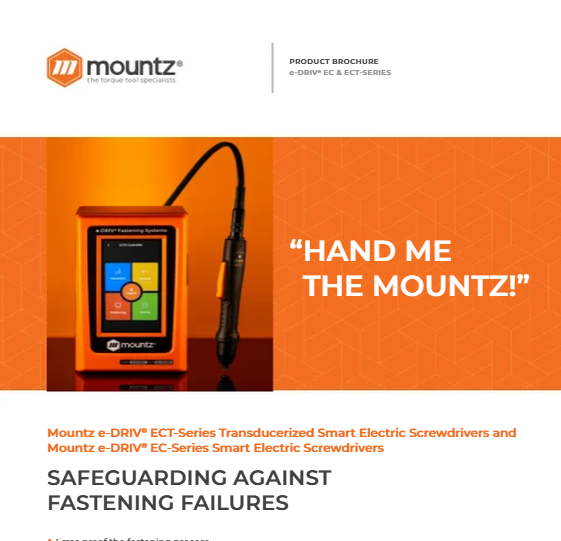

Mountz’s all-in-one transducerized smart electric screwdriver

solution safeguards against fastening failures for quality-minded

engineers with critical industrial manufacturing applications

requiring documented precision and accuracy torque control.

The EC and ECT-Series are available only through Mountz Torque,

a durable torque and automation control system engineered for

precise, accurate and repeatable torque control. The high-perfor

mance torque fastening system allows manufacturers to optimize

the assembly area, reduce labor costs and increase productivity.

Digital Torque Catalogs

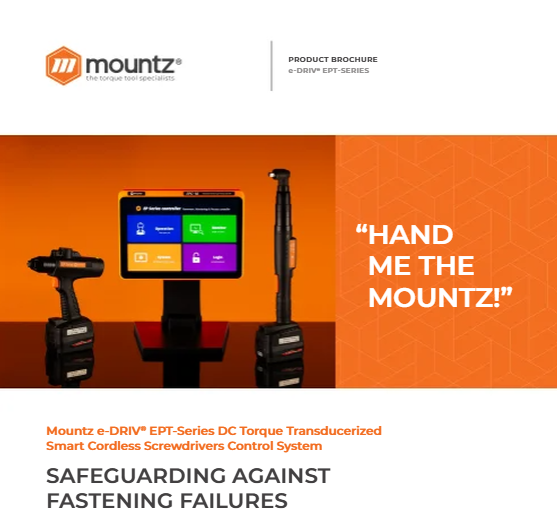

The all-in-one system that delivers productivity and quality advantages in complex manufacturing environments

Mountz’s all-in-one DC transducerized smart cordless screwdriver system safeguards against fastening failures for quality-minded engineers with critical industrial manufacturing applications

requiring documented precision and accuracy torque control. The EPT-Series are available only through Mountz Torque, a battery-operated torque and automation control system engineered for precise, accurate and repeatable torque control.

The lightweight, portable torque fastening system allows manufacturers to optimize the assembly area, reduce labor costs and increase productivity.

Digital Torque Catalogs

Engineered and assembled in Silicon Valley, the Mountz FG line of precision preset torque screwdrivers is the most advanced hand tool for high-level process and quality control. When under- or over-torquing puts your products at risk, Mountz cam-over torque screwdrivers deliver the accuracy you need. Mountz cam-over drivers utilize an internal cam-over mechanism to minimize the risk of operator error by disengaging once the desired torque is reached. Our cam-over technology increases consistency of torque delivered and joint reliability.

Digital Torque Catalogs

Engineered and assembled in Silicon Valley, the Mountz FG line of precision preset cleanroom torque screwdrivers are the most advanced hand tools for high-level process and quality control. The screwdriver’s repeatability, traceability, and precision safeguards against fastening failures. Designed for a cleanroom environment, the Mountz screwdriver is manufactured using a high-grade, low-outgassing powder coat.

The tools feature dynamic wear-resistant internal seals to prevent grease leakage and minimize airborne contamination.

Digital Torque Catalogs

Engineered and assembled in Silicon Valley, the Mountz FG line of precision preset ESD safe torque screwdrivers are the most advanced hand tools for high-level process and quality control. The screwdriver’s repeatability, traceability, and precision safeguards against fastening failures. Designed for ESD safe environment with sensitive electronic

components and assemblies, the Mountz ESD screwdriver adhere strictly to IEC standards, safeguarding against electrostatic energy and ensuring the utmost protection for delicate electronics. The tool features a dynamic wear-resistant

internal seals as an added protective measure to prevent grease leakage and contamination from infiltrating sensitive areas or components.

Digital Torque Catalogs

Engineered and assembled in Silicon Valley, the Mountz FGC line of precision preset cam-over wrenches are the most advanced torque wrenches for high-level process and quality control. The wrench’s repeatability, traceability, and precision safeguards against fastening failures. When under- or over-torquing puts your products at risk, Mountz cam-over wrenches deliver the accuracy you need. Mountz cam-over wrenches use an internal cam-over mechanism to reduce the risk of operator error by disengaging once torque is reached. Our cam-over technology increases consistency of torque delivered and joint reliability.

Digital Torque Catalogs

Engineered and assembled in Silicon Valley, the Mountz FGC line of precision preset cam-over wrenches are the most advanced torque wrenches for high-level process and quality control. The wrench’s repeatability, traceability, and precision safeguards against fastening failures. When under- or over-torquing puts your products at risk, Mountz cam-over wrenches deliver the accuracy you need. Mountz cam-over wrenches use an internal cam-over mechanism to reduce the risk of operator error by disengaging once torque is reached. Our cam-over technology increases consistency of torque delivered and joint reliability.

Digital Torque Catalogs

Engineered and assembled in Silicon Valley, the Mountz TBX line of precision preset break-over wrenches ensures consistent process and quality control. The wrench's repeatability, traceability,

and precision safeguards against fastening failures. When under- or over-torquing puts your products at risk, Mountz break-over wrenches help support your quality control process by empowering an operator to prevent assembly errors. Designed

to tighten various types of fasteners accurately, the break-over wrench informs the operator when the proper torque is reached by deflecting at the pivot point near the tool's end. The unique break-over mechanism gives an operator ample time to react once the target torque is achieved and stop applying additional force to the fastener. Our break-over technology increases the consistency of torque delivered and joint reliability.

Digital Torque Catalogs

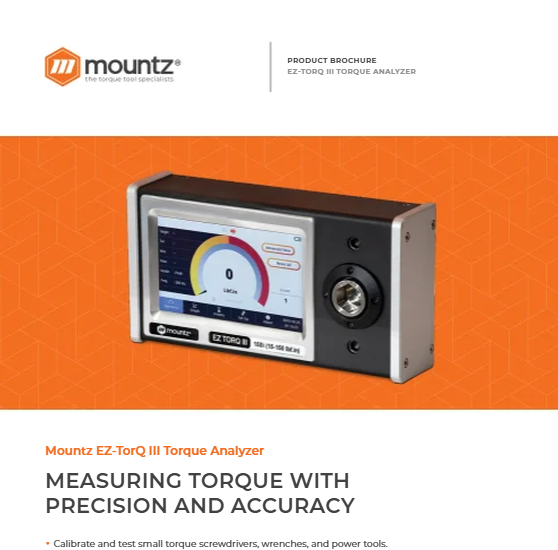

The Mountz EZ-TorQ III torque analyzer makes torque testing easy and mobile from calibration labs to assembly stations. Regular tool calibration and torque testing processes help manufacturers ensure repeatable accuracy and adherence to international standards. Companies must control torque to ensure their product’s quality, safety, and reliability aren’t compromised. A torque analyzer is a vital instrument for a quality control program. Investing in a torque testing solution eliminates downtime and expenses for shipping tools back and forth to an outside service center. It allows you to calibrate instruments more often and reduce calibration turnaround times and costs.

Digital Torque Catalogs

Ensuring seamless operations is no

simple feat. In a world where every

second counts, swift repairs and

precise calibrations are paramount –

and that's precisely what we promise to

deliver. At Mountz, we understand the

urgency of keeping your assembly tools

functioning flawlessly and compliant

with international standards through

routine calibration.

Digital Torque Catalogs

With 58 years of trusted expertise in torque

manufacturing, Mountz stands as a beacon

of reliability in torque calibration services.

Our seasoned technicians boast unparalleled

training, ensuring meticulous calibration and

repair work with an unwavering commitment

to quality control and safety standards.

Digital Torque Catalogs

Mountz torque arms offer a solution that goes beyond just functional performance—they improve the health and safety of your workplace. Ergonomically designed to reduce fatigue, Mountz torque arms help protect your workers from repetitive motion injuries while boosting overall productivity. By allowing operators to guide power tools effortlessly and absorbing torque reactions, these arms minimize physical strain and create a more comfortable work environment. Improve process control by preventing cross threading and sideload occurrences by keeping power tool perpendicular alignment.

Digital Torque Catalogs

Mountz linear torque arms absorb the torque reaction emitted from power tools, enhancing operator comfort and reducing fatigue. The torque arms are perfect for applications requiring precise horizontal (linear) motion. These arms provide ergonomic support by allowing operators to easily guide tools, reducing physical strain and preventing repetitive motion injuries.

Video

Minimize the risk of fastening errors and improve production efficiency with this intelligent error-proofing solution. Designed to integrate seamlessly with Mountz ECD, ECTD, DPC Touch or MDC controllers, this system automatically selects the correct torque or preset program based on the bit or socket chosen—no manual input required.

Video

The Mountz TBX line of precision preset break-over wrenches ensures consistent process and quality control by providing operators with a break-over wrench that helps you support your quality control inspectors by empowering your workers to prevent assembly errors. Torque range suitable for low to higher-torque applications.

Video

Mountz articulated torque arms absorb the torque reaction emitted from power tools, enhancing operator comfort and reducing fatigue. The torque arms provide exceptional agility, making them perfect for complex and dynamic tasks. These arms enhance ergonomic support by allowing operators to maneuver tools precisely and efficiently, significantly reducing physical strain and preventing repetitive motion injuries.

Video

Minimize the risk of fastening errors and improve production efficiency with this intelligent error-proofing solution. Designed to integrate seamlessly with Mountz ECD, ECTD, DPC Touch or MDC controllers, this system automatically selects the correct torque or preset program based on the bit or socket chosen—no manual input required.

Video

Mountz telescoping torque arms absorb the torque reaction emitted from power tools, enhancing operator comfort and reducing fatigue. The torque arms are engineered to handle the weight and reaction forces of torque tools, offering robust support and enhanced operator comfort. These arms are ideal for applications that require strong, lightweight, and flexible solutions.

Video

The Mountz FGA adjustable torque screwdriver is an error-proofing tool that allows engineers to reduce the risk of over-torque on their assembly lines in production environments with critical fasteners often found in electronics, aerospace, and automotive manufacturing. Torque range suitable for micro, low, and medium torque applications.

Video

The FG ESD tool is an expansion of the Mountz FG hand torque tool brand engineered with Mountz cam-over technology. Designed for an ESD-safe environment with sensitive electronic components and assemblies, the Mountz ESD screwdriver adheres strictly to IEC standards, safeguarding against electrostatic energy and ensuring the utmost protection for delicate electronics.

Video

Minimize the risk of fastening errors and improve production efficiency with this intelligent error-proofing solution. Designed to integrate seamlessly with Mountz ECD, ECTD, DPC Touch or MDC controllers, this system automatically selects the correct torque or preset program based on the bit or socket chosen—no manual input required.

Video

The Mountz EZ-TorQ III torque analyzer makes torque testing easy and mobile from calibration labs to assembly stations. Regular tool calibration and torque testing processes help manufacturers ensure repeatable accuracy and adherence to international standards. Companies must control torque to ensure their product’s quality, safety, and reliability aren’t compromised.

Video

The FG cleanroom tool is an expansion of the Mountz FG hand torque tool brand engineered with Mountz cam-over technology. Designed for a cleanroom environment, the Mountz screwdriver is manufactured using a high-grade, low-outgassing powder coat. The tools feature dynamic wear-resistant internal seals to prevent grease leakage and minimize airborne contamination.

Video

Minimize the risk of fastening errors and improve production efficiency with this intelligent error-proofing solution. Designed to integrate seamlessly with Mountz ECD, ECTD, DPC Touch or MDC controllers, this system automatically selects the correct torque or preset program based on the bit or socket chosen—no manual input required.

Video

Mountz LTT-Series torque analyzers provide engineers and metrology professionals with an advanced solution for calibrating, verifying, and maintaining tool performance. It is compatible with Mountz’s reaction and rotary sensors, including the ones with angle measurement capacity.

Video

Mountz Mini MDT-Series transducerized smart screwdriver systems provide engineers and operations with the latest micro torque fastening system with error-proofing technology that eliminates manufacturing risks and prevents product defects.

Video

Mountz linear torque arms absorb the torque reaction emitted from power tools, enhancing operator comfort and reducing fatigue. The torque arms are perfect for applications requiring precise horizontal (linear) motion. These arms provide ergonomic support by allowing operators to easily guide tools, reducing physical strain and preventing repetitive motion injuries.

Video

Mountz articulated torque arms absorb the torque reaction emitted from power tools, enhancing operator comfort and reducing fatigue. The torque arms provide exceptional agility, making them perfect for complex and dynamic tasks. These arms enhance ergonomic support by allowing operators to maneuver tools precisely and efficiently, significantly reducing physical strain and preventing repetitive motion injuries.

Video

The Mountz Torque EPC-10 Controller can be paired with any EPT, an all-in-one transducerized smart cordless screwdriver, to improve process manufacturing reliability and efficiency. With intelligent fastening strategies and high-precision torque accuracy - engineering can program the EPT to guide the operator through the assembly process with instructions and visual target data for each fastening position. After completing the process, your team can analyze fastening data to improve your manufacturing process.

Video

It doesn't require much force to over-torque miniature fasteners in critical applications for life-saving medical devices, aerospace instruments and microelectronic components. The mini FG preset screwdriver allows an engineer to ensure that the correct torque value is consistently applied to each miniature fastener and prevents costly over-torque events.

Video

Mountz Torque FG -OWC (one-way clutch) torque screwdrivers use a one-way torque clutch system designed to apply torque in one direction and remain positive in the opposite direction, which allows the tool to be used for easy screw removal. Torque range suitable for micro, low, and medium torque applications.

Video

A torque sensor is a versatile measurement instrument that allows engineers to expand torque calibration and testing capacity. Mountz Torque BMX torque sensors make it easy to meet the demands of testing multiple torque ranges for torque tools used in production, maintenance, and calibration labs.

Video

The Mountz EPT is an all-in-one transducerized smart cordless screwdriver solution built for reliability and efficiency in a high-tech manufacturing process. With innovative fastening strategies and high-precision torque accuracy, the EPT provides manufacturers with the flexibility of a cordless tool with the latest error-proofing and traceability benefits - helping to reduce manufacturing defects and improve productivity.

Video

Regular tool calibration and torque testing processes ensure repeatable accuracy and adherence to international standards. With its easy-to-use touch-screen interface, the Mountz EZ-TorQ III torque analyzer provides quick and easy torque tool validation and calibration.

Video

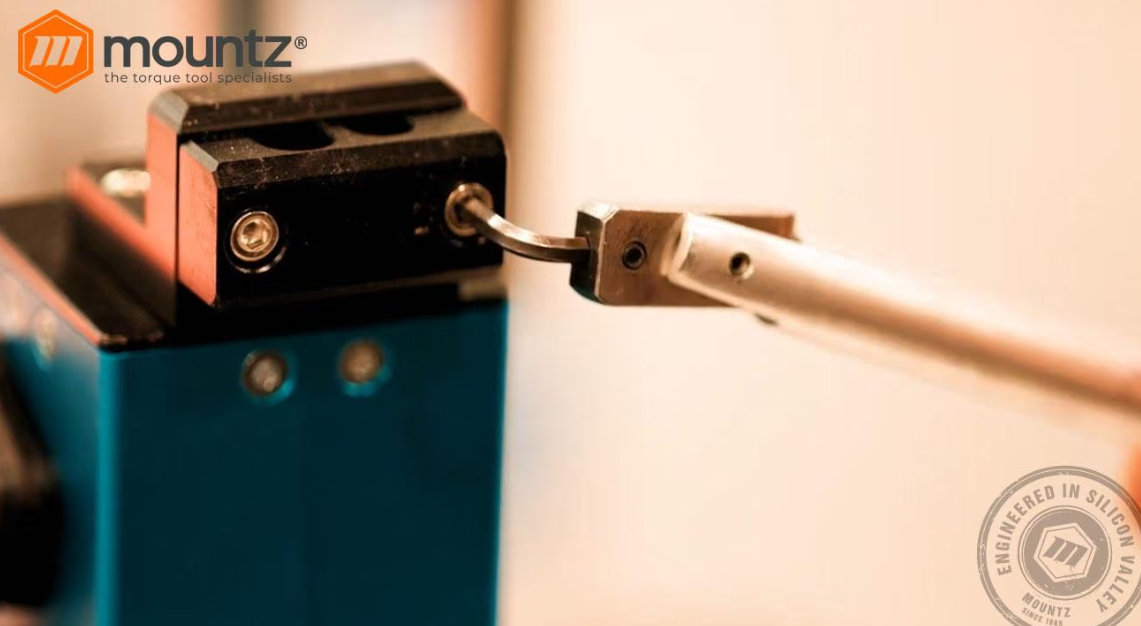

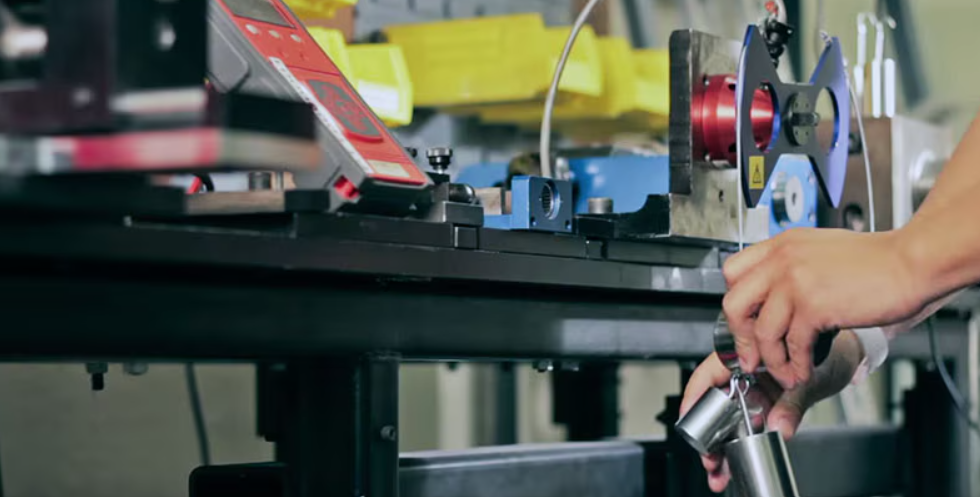

When paired with a torque analyzer, the RTSX rotary torque sensor is the ideal torque auditing tool for testing the torque applied to a fastener for assembly applications. By connecting a rotary torque sensor between a hand, electric screwdriver, or pneumatic tool during the fastening process, you can monitor the torque applied from the tool to a screw or bolt. The measurement results allow a user to verify that the tool is within its calibration limits, preventing under or over-torque fasteners that result in costly product defects and long-term liability results.

Video

Mountz FG-IFR (Impact Free Resetting) preset screwdrivers use a cam-over mechanism to improve process control and productivity. The unique IFR cam over design provides a low-impact reset mechanism, ideal for assembling shock-sensitive components that reduce the vibration transmitted in the screw tightening process—ideal for fastening delicate parts such as electronics, plastics, and medical devices. Torque range suitable for micro, low, and medium torque applications.

Video

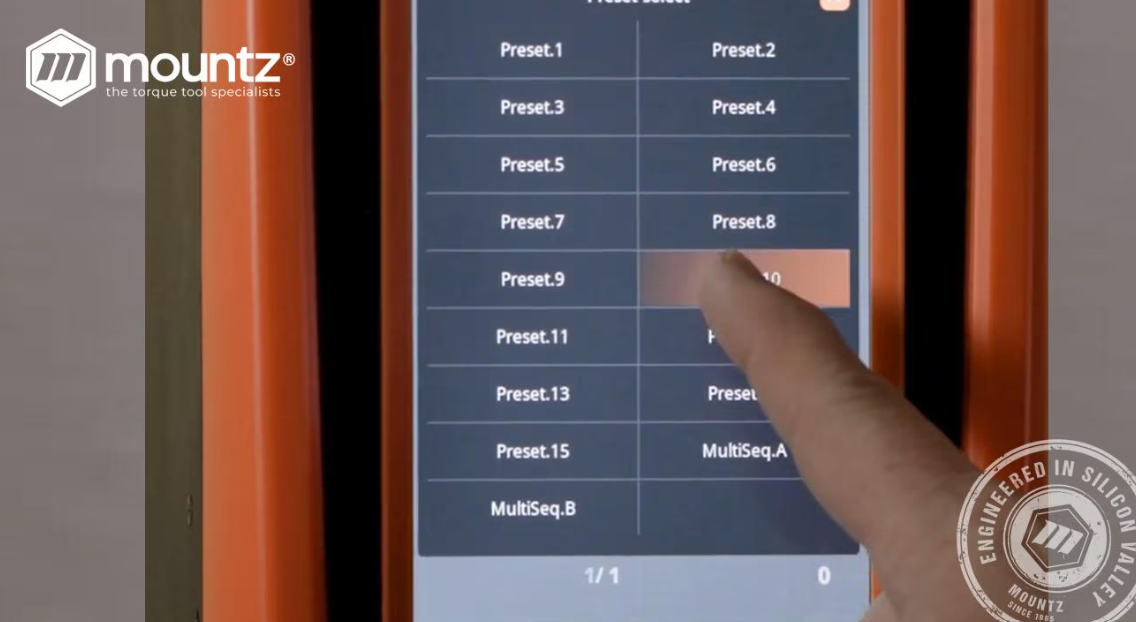

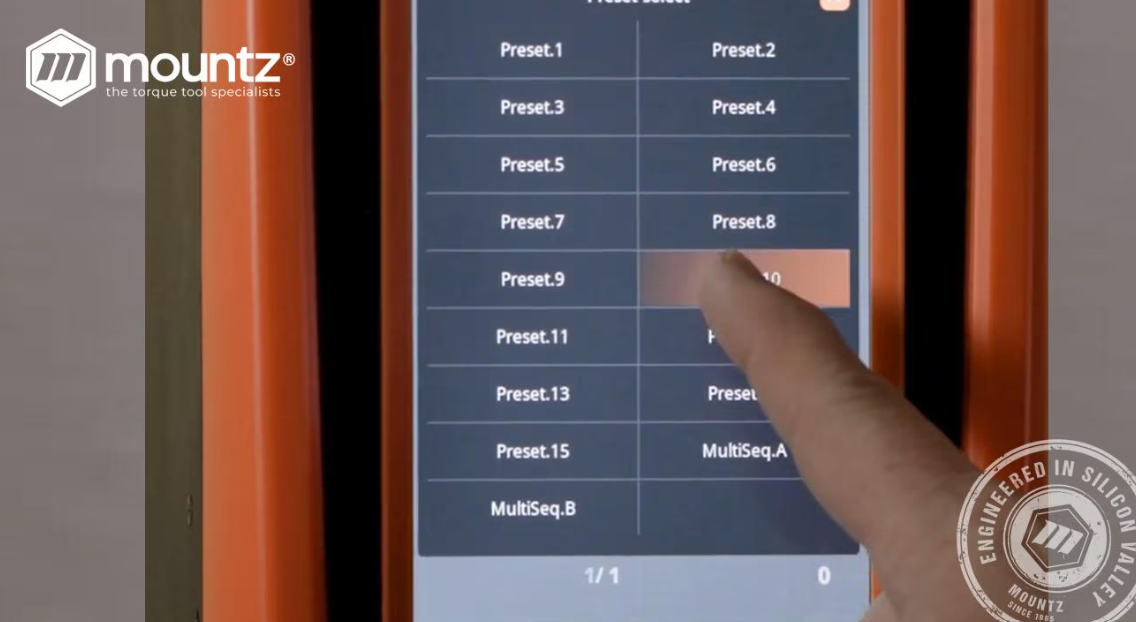

Manufacturing applications that use various screws and torque settings require different tools to tighten the fasteners. A single Mountz smart electric screwdriver system can replace up to 15 tools. The Mountz DC control tools are easy to program and can remember up to 15 fastening preset settings with 30 process sequences and 20 program steps. The tool allows you to carry out varied and complicated manufacturing plans. The assembly tool reduces tooling costs and improves operations by optimizing a company’s manufacturing footprint.

Video

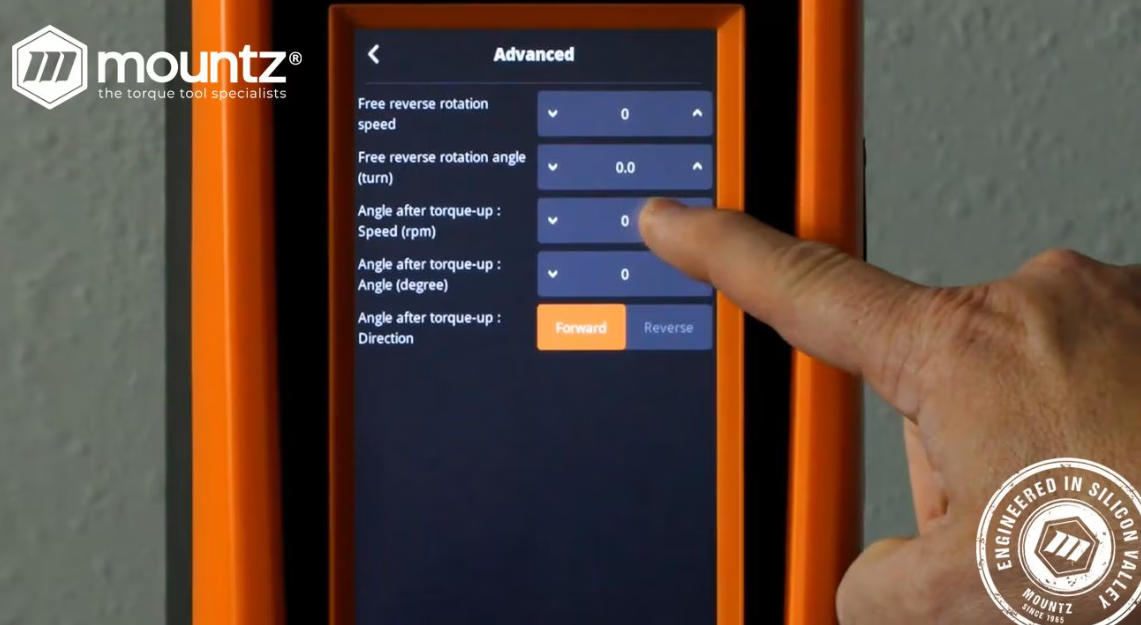

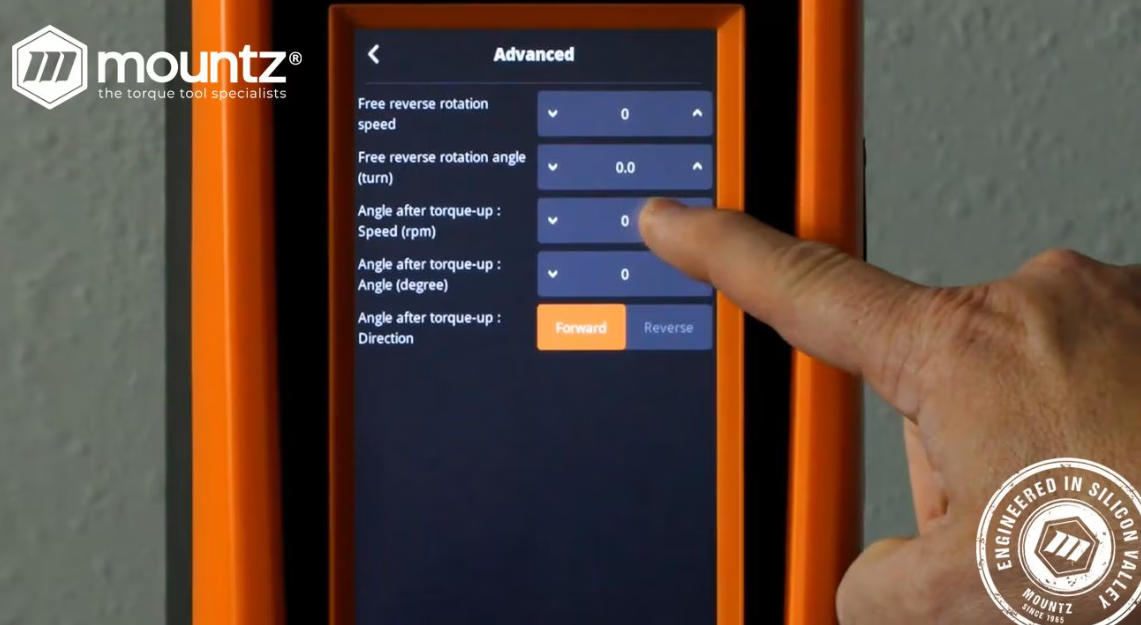

Do you use fine-thread fasteners that are susceptible to cross-threading events? You can utilize the "free reverse" function with the Mountz smart electric screwdrivers systems. This feature starts a fastener in the reverse direction for a preset number of rotations and RPM setting to allow the fastener to be fine with the thread. Then smart electric screwdriver automatically starts the fastening direction and finishes the tightening process.

Video

How do you prevent an over-torque event for a fastening application? The FGC wrench is engineered with a cam-over technology and prevents over-torque. The cam-over mechanism physically prevents the operator from over-torquing fasteners. Selecting a poka-yoke tool improves process control and reduces scrap rates.

Video

The EPC-10 wireless controller operates with the EPT-Series transducerized smart cordless screwdrivers. The controller can monitor and collect fastening and event data for up to 8 wireless EPT battery screwdrivers. As cordless tools are used independently, the fastening and event are sent to the EPC-10 controller in real time once the operation is completed. If communication is interrupted, the cordless screwdriver stores the readings in the tool memory. And when communication is restored, the data is sent to the controller.

Video

The Mountz smart electric screwdriver system offers a parameter setting option for an assembly application requiring torque and angle operation. The ECT and EC-Series electric screwdrivers allow a fastening process to torque a fastener to a preset value and then rotate a designated amount of degrees.

Video

Faster than hand tools, electric torque screwdrivers are ideal for high-volume assembly operations where speed is of the essence. These tools can either be operated by assembly workers or robotic applications. The NF-Series brushless electric screwdrivers add precision and repeatability to the assembly process.

Video

If you want to add an extra layer of error-proofing to your fastening process, you can select the "Fastening Stop Error" alert with the Mountz smart electric screwdriver system. When the operator is fastening a screw and if they release the power tool's trigger prematurely before the operation process is completed, the screwdriver system will alert the operator with an error notification. The operator will need to finish the fastening process.

Video

Do you need an easy means to view a graphical representation of the fastening joint? The Mountz EPT and ECT smart electric screwdriver systems offer this function. The graphing features with EPC-10 and ECT controllers allow you to view in display in real-time the graph of the torque, speed, and angle data. Collect and store essential quality data in a repository for data analytics, regulatory compliance, and traceability with Mountz smart screwdrivers.

Video

Regular tool calibration and torque testing processes ensure repeatable accuracy and adherence to international standards. With its easy-to-use touch-screen interface, the Mountz EZ-TorQ III torque analyzer provides quick and easy torque tool validation and calibration.

Video

When under or over-torquing puts your products at risk, a break-over wrench can help support a quality control process by empowering an operator to prevent assembly errors. The break-over wrench tightens fasteners accurately and informs the operator when the torque is reached by deflecting at the pivot point near the tool's end. The unique break-over mechanism gives an operator ample time to react once the target torque is achieved and alerts them to stop applying additional force to the fastener.

Video

When testing the torque calibration of a tool, you can set up a target for the tool along with the tolerance percentage of that torque setting. The EZ-TorQ III torque analyzer's touchscreen interface makes it simple and easy to set up torque testing parameters for a tool.

Video

The Mountz smart electric screwdriver allows you to program multiple torque preset values and fastening steps into a single rundown event. Group similar processes and assign standardized tasks: program fastening sequences and torque tolerances for each fastener in a sequence for sensitive and complex assembly joints. You can achieve multiple fastening tasks with one tooling system. The Mountz EC or ECT-Series can store up to 30 process sequences with 20 program steps.

Video

When fastening long screws with the EC or ECT smart electric screwdrivers, are you looking for efficiency and accuracy? The auto-customizing feature learns the characteristic of the rundown and will automatically program the free angle. This process allows the tool to operate at a high RPM and then automatically slow down to a low fastening RPM speed for the end tightening process, allowing for smooth torque. This auto speed setting feature helps prevent over torque by speed shock.

Video

With select Mountz brushless electric screwdrivers, it offers a soft start speed function. This feature allows you to set the initial speed ramp for a fastening application. You adjust the starting speed of an electric screwdriver for a slow rotation, which allows for smooth engagement between fasteners and parts. It helps prevent cross-threading events.

Video

.jpg)

The EPT cordless screwdriver features a built-in bar code scanner. The bar code scanner allows the operator to instantly select and activate a programmed fastening event on the controller. A bar code scanner can scan the bar code to trigger the correct event and capture and record the data for each run down by assigning a bar code to a fastening event. This capability is an error-proofing technique that permanently links the fastening data with the correct part.

Video

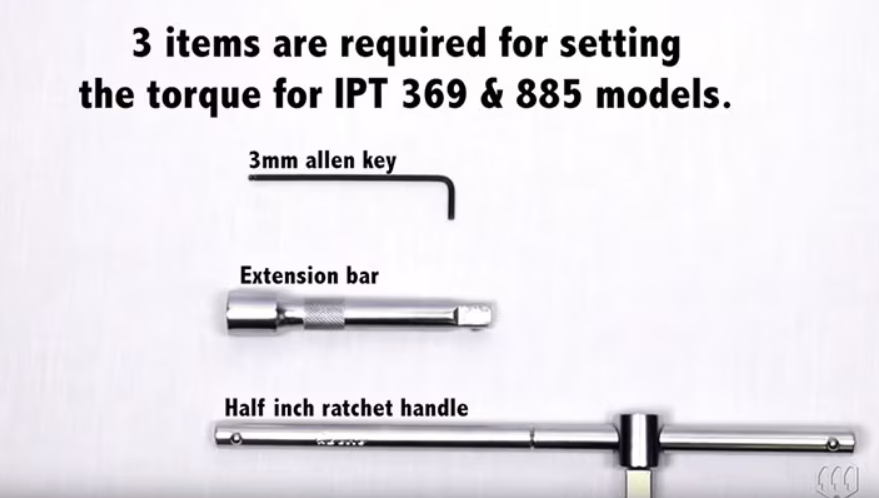

An IPT preset click wrench securely prevents an operator from either incidentally or intentionally tamper with a tool's torque setting. Preset torque wrenches are typically used for production applications where there is one torque setting required. However, if the torque specification changes or a new project requires a different torque setting, the preset torque wrench is still flexible enough that a new torque setting can be set.

Video

.jpg)

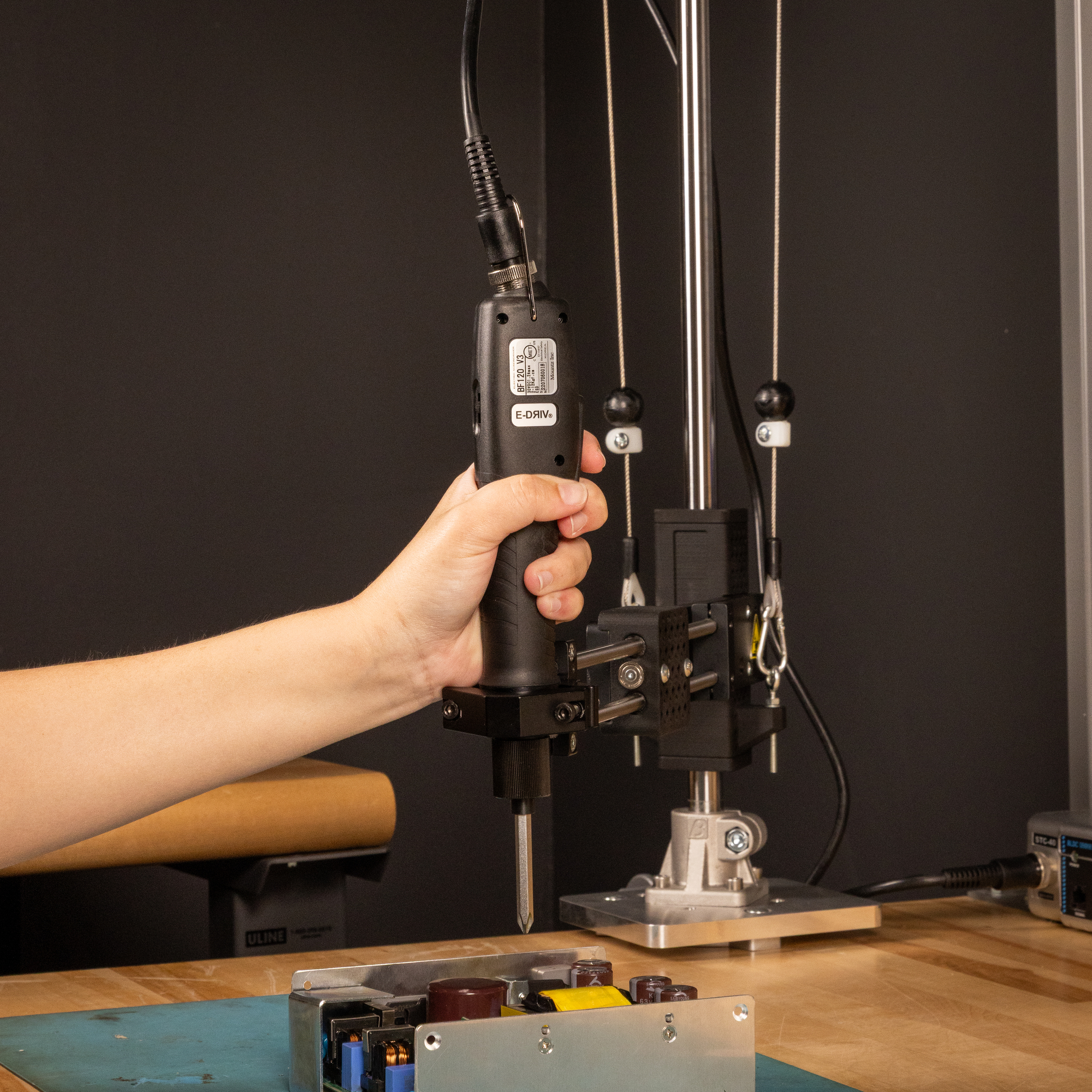

Designed for high production environments, the E-DRIV BF-Series feature a high performance brushless motor design that provides durability and reduces the standard maintenance costs for electric screwdrivers. Mountz offers a variety of models including BF brushless electric screwdriver with an adjustable RPM setting directly on the tool as well as a selectable "Soft Start" option.

Video

The MD-Series DC torque control system is a high-performance fastening system that allows manufacturers to optimize the assembly area, reduce labor costs, enhance quality and increase productivity. The durable torque and automation control system is engineered for precise, accurate and repeatable torque control.

Video

The EZ-Glider Position Control torque arms by Mountz Inc. help manufacturers detect and eliminate costly screw-fastening errors during the assembly process. Position Control torque arms are designed to reduce the risk of improperly fastened screws, ensuring that every screw is in the correctly tightened in the correct sequence. Using the EZ-Glider Position Control torque arm is like putting the eyes and ears of a quality control manager where they are needed most - right on the assembly area.

Video

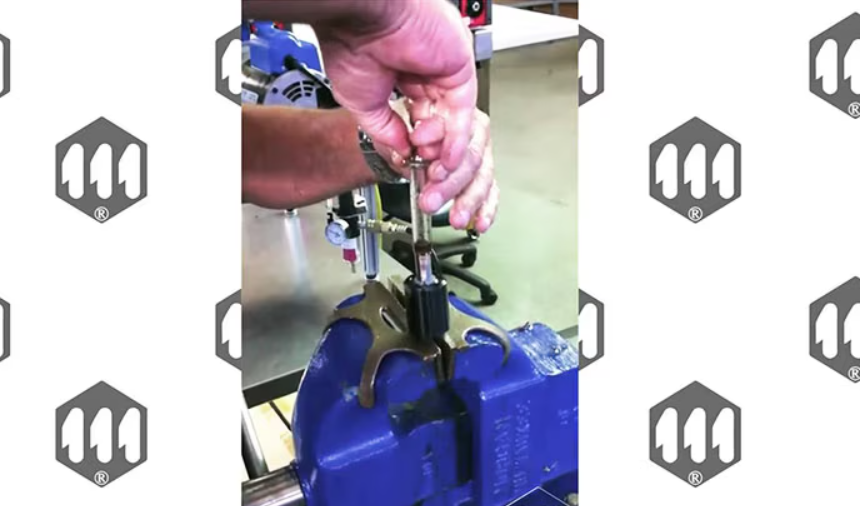

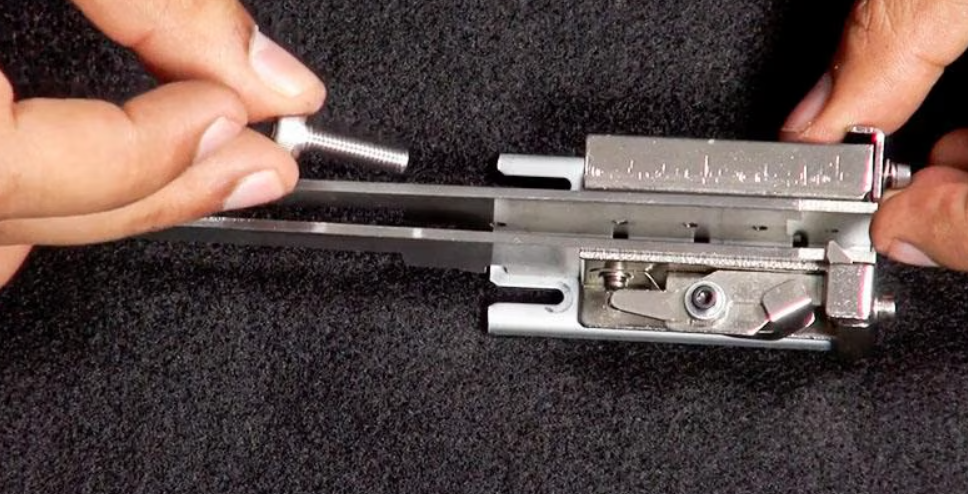

The video above provides a guide for making the final adjustments needed to operate the MSP screw presenter proficiently. These key adjustments help control the speed and efficiency of the screws being presented. The "best-practice" approach to ensure the screw presenter is functioning suitably for your assembly application is to operate the screw presenter with your screws a few times and conduct any fine-tuning adjustments as needed with the device.

Video

When calibrating a click wrench it is recommended to follow ISO6789 International Standard requirements. The standard covers things such as calibration methods, design requirements, and tool types. For calibrating a torque wrench, either use a torque tester or torque sensor within the range of the torque wrench. A torque wrench is a precision tool and should be treated and maintained like a measuring instrument. A torque wrench must be properly calibrated and maintained on a regular preventative maintenance and calibration schedule. Learn more on how to perform the wrench calibration.

Video

The EPT is an adjustable click wrench that provides different setting options for applications that require more than one torque value. The adjustable wrench features an external adjustment torque scale, which allows an operator to adjust the torque setting on the tool as needed. The EPT wrench offers an easy-to-read dual scale system (American & S.I.) with a laser marked scale along the body tube section of the wrench. The robust tool is ideal for field service, maintenance and production applications.

Video

Torque calibration equipment is the official means by which torque testers and torque sensors are calibrated and are traceable to National or International Standards, such as N.I.S.T, ISO. Mountz offers Calibration Wheels and Segment Arms for calibrating torque testers and torque sensors. These calibration instruments enable easy and accurate torque measurement and torque calibration. Torque analyzers and torque sensors go out of calibration with use. Calibrating these instruments is a fine-tuning process of bring the equipment back within in tolerance.

Video

An electric torque screwdriver is a precision torque control instrument and should be handled with care at all times. There are different methods for testing the torque output of an electric screwdriver. Each method has a key purpose. The video above provides a brief overview of the different methods. Measuring torque is a continuous process. Testing and auditing an electric screwdriver should be part of assembly process. As part of the overall quality control process, manufactures should include a "Torque Auditing" program.

Video

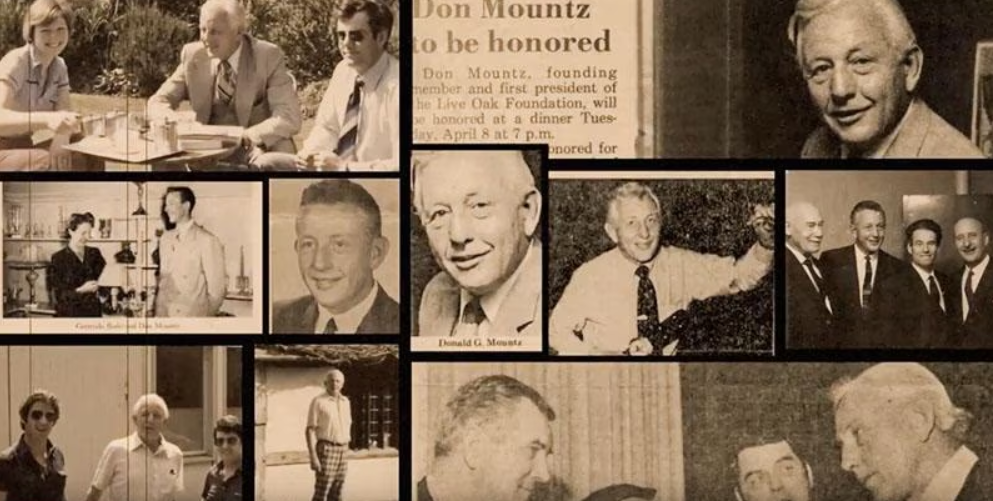

The world of manufacturing has evolved rapidly in the last 50 years. Mountz was founded by Donald Mountz in 1965 with a passion to provide the highest quality torque tool products & customer service to world-class manufacturing companies. This year marks the 50th anniversary for Mountz Inc. in business. Without quality and torque control, our daily lives would not be the same. One constant in the last 50 years, the core purpose of Mountz is to make a safer world through accuracy and precision. There have been many changes within our culture, technology and manufacturing in the past 50 years, here are some fun and interesting milestones during that time frame with this video.

Video

The MTX is a low torque sensor designed for calibrating and testing small hand screwdrivers, torque wrenches and power tools. These versatile torque sensors are used in conjunction with a torque tester. Designed to perform static torque measurement, the small precision instrument can measure torque in both clockwise and counterclockwise direction. Mountz supplies a free ISO 17025 certification of calibration with the purchase of any new MTX torque sensor.

Video

The EF-Series power tools are built for tightening small screws, nuts and bolts. These mechanical clutch screwdrivers offer excellent fastening capability. The low-torque electric screwdrivers provide automatic shutoff capabilities for sensitive electronics or other low-torque applications. The electric screwdriver automatically stops when the preset torque value is achieved. The EF-Series electric screwdrivers are NRTL certified from TUV America, Inc. The certification ensures manufacturing companies are purchasing and operating quality and safe tool for its operators.

Video

.jpg)

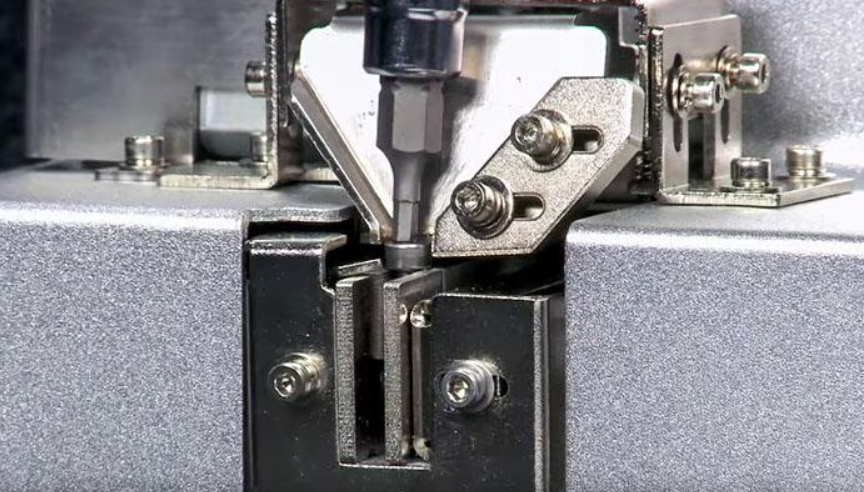

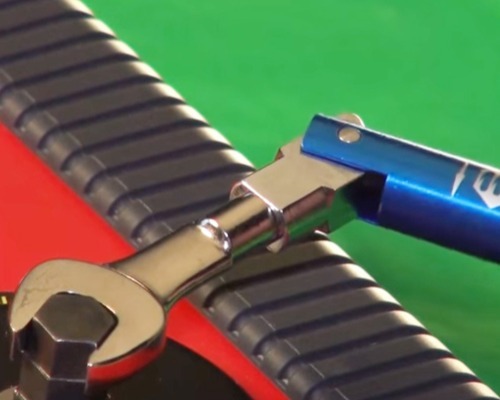

How do you connect a rotary torque sensor between a power tool and joint? The Mountz rotary torque sensors connect between the power tool and a fastener joint. The sensor monitors actual torque being applied from the driver to the fastener.

Video

The MSP is a small, tabletop screw presenters used to organize and automate work areas and production cells. Screw presenters make assemblers and the assembly process more efficient by mechanically presenting a screw to a fixed pick-up point. Conventional assembly methods cause assemblers to inefficiently fumble with screws that are stored in bins or shaker trays.

Video

The NF-Series electric torque screwdriver are the best-in-class and represents a major advance in design and engineering. The electric driver delivers accuracy, sound ergonomics, durability and versatility for most industrial assembly applications. Built for high production environments, the NF-Series tools feature a high-performance Swiss Maxon brushless motor design, which reduces the standard maintenance costs associated with most electric screwdrivers.

Video

The IPT is a preset click wrench (internally adjustable) by Mountz that ensures a reliable tightening process. A preset click wrench does not feature an external adjustment scale. These tools have an internal adjustment mechanism for setting the torque value and must be preset using a torque tester. Preset torque wrenches are typically used for production applications where there is one torque setting required. However, if the torque specification changes or a new project requires a different torque setting, the preset torque wrench is still flexible enough that a new torque setting can be set internally using a torque analyzer.

Video

A torque meter is a finely tuned instrument engineered for testing and monitoring torque applications. Designed for torque evaluation and verification, a torque meter is a laboratory grade instrument that is commonly used for quality control, R&D and calibration applications.

Video

Screw presenters make assemblers and the assembly process more efficient by mechanically presenting a screw to a fixed pick up point. For cell or line based assembly, an operator uses a magnetized bit or vacuum attachment to pick up a screw from the presenter screw guide. A magnetized bit will retrieve most screws from the screw presenter. For non-magnetic and stainless screws, an assembly tool will require a vacuum adapter kit to pick up fasteners from the screw presenter.

Video

Built for high production environments, the Mountz air screwdriver tools provide durability, power and speed for assembly and manufacturing applications at an affordable price. Designed for safe operation and increase comfort for operators, the air screwdrivers provide lower noise decibels than comparative pneumatic screwdrivers as well as minimal vibration and low torque reaction on the operator.

Video

The Flex Power pulse tools by Mountz are designed to enhance quality through precision torque control. But if the tool is not set up correctly, the pulse tool will not operate properly. Here are some quick tips for connecting a pulse tool to an airline. Be sure to use the proper air fitting and air hose size as stated for each pulse tool model. Teflon tape is needed when installing the air fitting. Always use the proper air hose length for the pulse tool. The length of an air hose shall not exceed 5 meters from the airline or the air pressure will reduce, which impacts the torque setting.

Video

A pulse tool has the speed of an impact wrench with nearly the repeatability of a clutch based shut-off torque tool. Containing precision-machined parts the pulse unit is a sealed chamber that is filled with a formulated hydraulic fluid. Pulse blades with a custom-designed precision roller push the fluid inside the rotating chamber generating hydraulic pressure that produces torque. Air power is the power source that spins the anvil and resistance against the fastener causes the pulse unit to activate.

Video

The pulse tool requires regular maintenance to ensure the tool operates at optimal performance. The type of routine maintenance and the frequency is dependent on the application and how the tool is used. The pulse tool requires preventive maintenance like oil changes and have the parts inspected periodically. Regular oil changes will increase the life cycle of the tool, reduce maintenance costs and allow the tool to operate properly.

Video

Electric torque screwdrivers are designed for precision torque control and ensure product quality, cost savings and a reduction in overall assembly failures. For low to medium volume production fastening applications, the K-Series from Mountz is a quality option to consider. These durable assembly tools increase productivity and enhance product quality through precision torque control and user comfort. The K-Series tools are available in Lever start, Push-to-Start and ESD options.

Video

Break-over wrenches improve control of the bolting process by reducing the risk of both over and under-tightening. Upon reaching the preset torque value, the tool "breaks" at a specific point along the tool's shaft — usually at a pivot point near the tool's head. The unique break-over mechanism provides an operator ample time to react once the target torque is reached and to stop applying any additional force to the fastener.

Video

Mountz offers the next generation of automation and process control in screw fastening technology. The robotic driver is a durable torque and automation control system engineered for precise, accurate and repeatable torque control. The high-performance robotic fastening system allows manufacturers to optimize the assembly area, reduce labor costs and increase productivity.

Video

The MSP screw presenters make assemblers and the assembly process more efficient by mechanically presenting a screw to a fixed pick up point. The screws are aligned along the screw-feeding rail with one fastener exposed and sitting in the bit guide. Once the bit of the power tool engages with the screw head and the fastener is removed, then another screw automatically dispenses to the bit guide and is ready for an easy pick-up. No fumbling with screws.

Video

Mountz Screw presenters are small, tabletop devices used to organize and automate work areas and production cells. Screw presenters make assemblers and the assembly process more efficient by mechanically presenting a screw to a fixed pick up point. For cell or line-based assembly, an operator uses a magnetized bit or vacuum attachment to pick up a screw from the presenter screw guide.

Video

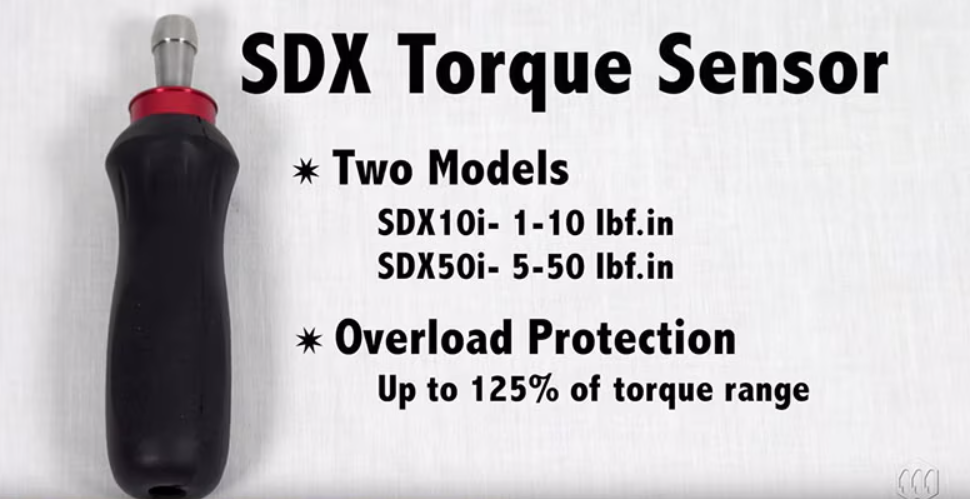

The Mountz SDX torque sensor is an instrument designed for torque auditing, verification or tightening fasteners. The SDX sensor connects to a torque tester and is used to accurately audit the residual torque on a previously tightened fastener. With a torque analyzer, you can capture and store the data results from the torque tests and then download the data to a PC. The sensor is used for three common torque verification tests: first movement test, loosening test or a marking test.

Video

Calibration is the method of comparing tools and measuring devices to higher accuracy standards. Torque calibration equipment is the official means by which torque testers and sensors are calibrated and are traceable to National or International Standards, such as N.I.S.T and ISO. A torque analyzer or a torque sensor are a finely tuned instrument designed for testing and monitoring torque applications. In order to maintain accuracy, it is crucial that torque measuring equipment be properly calibrated regularly.

Video

-1.jpg)

There are three styles in which the torque wrench can signal achieving torque: either by a click, break, or slip. Each of the three wrench styles has a specific purpose and utility. When you decide to spend the money for one, it is important that you select the one that will do the job properly and not generically.

Video

Pulse tools increase productivity and enhance product quality through precision torque control and user comfort. Regular tool calibration ensures repeatable accuracy and adherence to international standards. A pulse tool is a power tool that must be properly calibrated and maintained. Torque testing ensures the pulse tool is operating at peak performance and can highlight any potential tooling problems before they arise perhaps due to tool wear or broken components.

Video

Break-over torque wrenches are essential to limiting the amount of torque applied to an assembly or fastening. Break-over torque wrenches, typically deflect 20-90 degrees on torque delivery, thus indicating torque has been reached. Many break-over wrenches require manual resetting, while others have an automatic resetting feature.

Video

Assemblers fumble around with screws daily during the fastening process. The repetition of grabbing small fasteners from a bin is tedious and time-consuming. The constant repetition of picking-up and fumbling around with hundreds and hundreds of screws on a daily basis impacts productivity and costs. It's an unnecessary expense and an inefficient process. Also, a potential health hazard if fasteners are dropped and left on the floor, allowing an opportunity for an individual to slip and fall.

Video

When calibrating or testing torque wrenches, often adapters are needed. Especially wrenches with open-end heads. An adapter that features four common sizes will increase productivity. A calibration hex step adapter by Mountz is your solution. The hex adapter makes it easy and convenient to test a common range of open-ended wrenches.

Video

The MSP screw presenter is a simple machine to operate. The fasteners are poured into the hopper of the screw presenter and automatically line up for dispensing. This simple mechanism allows trouble-free operation, eliminating jammed or stuck screws. The screws are aligned along the screw-feeding rail with one fastener exposed and sitting in the bit guide.

Video

A pulse tool has the speed of an impact wrench with nearly the repeatability of a clutch based shut-off tool. Containing precision-machined parts the pulse unit is a sealed chamber that is filled with a formulated hydraulic fluid. Pulse blades with a custom-designed precision roller push the fluid inside the rotating chamber generating hydraulic pressure that produces torque. Air power is the power source that spins the anvil and resistance against the fastener causes the pulse unit to activate.

Video

The ergonomic torque arms by Mountz eliminate torque reaction from both power and pneumatic assembly tools. With the EZ-Glider linear and articulated torque arms, a "downward assistant kit" can be installed on the arm to speed up and improve the production process. The system requires no effort from the operator to press downward on the power tool. An assembly operator simply guides the power tool and the cylinder automatically glides the torque tool downward. These kits are ideal for self-tapping applications, as well as other fastening applications.

Video

With over 55 years of experience, Mountz is a pioneer in developing torque sensors and torque testers. The Mountz BMX torque sensor is a bench mounted torque sensor designed for both measuring torque as well as calibrating torque tools. The versatile unit can be used in both a calibration lab environment or out on the production floor. Using a quality sensor is key for many companies to ensure that the proper torque is being applied. Testing torque is literally a science and not something that can be left to chance.

Video

Torque is not something that we think about on a daily basis. We may never think about its importance or what it provides to us. Torque impacts our daily lives. Torque surrounds us. Millions and millions of 4,000-pound automobiles zip along the roads daily. Twelve-ton jets ascend to our skies hourly transporting our colleagues, our friends and our families. Satellites seamlessly orbit around our planet. At our fingertips, our modern electronics provide us with instant communication with the world. All these items are assembled with fasteners and quality torque tools.

Video

A dial torque wrench from Mountz is a reliable way to ensure your torque needs are being met. These measuring tools can be used as an assembly tool, but are best used as a quality control instrument to verify or monitor torque. For torque auditing and measurement applications, a dial wrench is alternative solution to a digital wrench for performing a quick visual torque verification test.

Video

Torque tools go out of calibration with use. Calibrating a torque tool is a fine-tuning process of bringing the tool back within its tolerance. Torque testers can also be used for quick tools tests on the line or in the lab to determine whether torque tools are holding a given setting.

Video

The preset click wrench securely prevents an operator from either incidentally or intentionally tamper with a tool's torque setting. Preset torque wrenches are typically used for production applications where there is one torque setting required. However, if the torque specification changes or a new project requires a different torque setting, the preset torque wrench is still flexible enough that a new torque setting can be set.

Video

The Loading Bench by Mountz Inc. is a laboratory grade instrument designed to enable accurate torque wrench calibration with less physical effort. The Loading Bench simulates torque application conditions with minimum effort and enhanced safety for the calibration technician assuring a more accurate calibration. The calibration instrument enables quick and easy torque wrench calibration and presetting, independent of human influence or transducer side and end load factors. The Mountz Inc. Loading Bench is designed to calibrate torque wrenches in accordance with International Standards ISO6789:2007.

Video

Built for high production environments, FlexPower pulse tools provide durability, power and speed for most industrial assembly applications. To maintain consistent accuracy, the torque output for pulse tools must be verified periodically. You should also validate the actual torque being applied to the fastener by auditing the joint application. The goal for auditing is to verify adequate torque was delivered to the fastener and detect any loose fasteners or joint relaxation.

Video

Small torque tools go out of calibration with use. To maintain consistent accuracy, small torque tools must be checked periodically for wear or defective parts. A small power or hand torque tool is a measuring tool that must be properly calibrated and maintained.

Video

The auto-reversing run down adapter (AURA) is engineered to provide consistent and reliable torque readings when testing power-driven torque control tools with a torque tester or torque sensor. The run down adapter is mounted in-line between the tool drive and the transducer. The device reduces the impact and irregular peaks that cause poor repeatability.

Video

Once you have selected the electric screwdriver for your fastening application, it's important to understand the basic function and proper setup for the tool. Always use the proper supporting equipment and read the operating instructions before operating an assembly power tool. Do not misuse the tool for an incorrect tightening application.

Video

The LF-Series is an economical brushless electric torque screwdriver. The durable power tool features a Swiss Maxon brushless motor design. A brushless motor provides an extremely long operating life and extends the intervals between routine maintenance schedules. Electric screwdrivers with brushless motors have low maintenance requirements and eliminate the need for replacing the common expendable parts associated with non-brushless screwdrivers such as carbon brushes, rotors, switches and other contact points.

Video

The video is a how-to guide for installing and updating the LTT torque analyzer software. The LTT is a Mountz torque analyzer used to measure torque, calibrating tools, torque auditing, and torque verification applications.

Video

What is the relationship between torque and friction? The process of tightening a fastener involves various elements. The friction behavior between the fastener and the joint is critical to secure the desired clamp load. Torque and friction go together like peanut butter and jelly or nuts and bolts.

Webinar

How often do you verify the calibration of a power tool and ensure repeatable performance? Over time or with usage, these tools drift out of tolerance, and the risk of reliability increases. Maintaining accuracy, repeatability, and safety quality standards is a significant benefit for validating the power tool's status.

Webinar

Implementing a solution that prevents over-torque events is critical for engineers to reduce scrap rate costs. Applying the right amount of torque to each fastener maximizes its holding potential. Over-torquing a fastener generates risks of fastening failures and damaged products.

Webinar

Power-driven screwdrivers are suitable for an assortment of assembly applications. Determining the right electric screwdriver for your fastening application is a challenging process.

Webinar

Measuring torque is essential for manufacturers to ensure a product's quality, safety, and reliability aren't compromised. A torque sensor is a finely tuned instrument for testing and tool calibration.

Webinar

In cleanroom-critical industries like Optics, Semiconductors, Aerospace, and Medical Devices, precision and cleanliness are non-negotiable. Even microscopic particles or trace VOCs such as grease vapors can compromise system performance or cause permanent damage to sensitive components.

Case Study

A helicopter manufacturer had a critical torque application during the routine maintenance process of their aircraft. The rotor of the helicopter requires servicing after every 20 hours of flight. Some of these aircraft are serviced in very remote locations, where air or power is not readily available or reliable. Ensuring proper torque control is achieved for the rotor assembly nut is a critical element for maintaining the continuous safe operation of the helicopter.

Case Study

.jpg)

A manufacturer of heavy-duty trailer suspensions was looking for an option to verify torque and tension on suspension bolts used on current products and on new products that were in development.

Case Study

A product support engineer from a medical manufacturer needed to develop a process that would assure system installation contractors could tighten large bolts on a 4000 lb rotating counterweight to a torque specification of 750 lbf ft. Accessibility to fasteners was limited and precluded the use of pneumatic or hydraulic torque multipliers. It was imperative that contractors properly torqued the fasteners to prevent potential liability that could result if counterweight came free and injured a patient.

Case Study

Deep down in a coal mine, the foreman faced lengthy and costly dilemmas for two key maintenance applications. The first maintenance application was for removing and re-tightening the bolts during the servicing process for "Mining Heads" used on the industrial machines attached to the vehicles underground. The "Mining Heads" are used to channel through rock and extract the coal from the underground mine. Being the deepest coal mine in the US, 5 miles deep, bringing these Mining Heads out of the mine each time for service was not economical and would create too much down time. It would take 4 days to bring the Mining Heads to the surface.

Case Study

A rail yard in Canada was searching for a torque solution that would speed up the process and remove strain on its operators. The application was to assist their operators raise and lower the decks on the AutoMax rail cars in preparation of loading new cars at a local automotive manufacturing plant.

Case Study

An electronics manufacturing company uses torque testers along with benched mounted torque sensors to audit 150+ pneumatic torque tools on a daily basis. Each pneumatic tool has bar-code on it, which identifies the tool. A unique tool test (torque setting and tolerance setting) is set-up for each pneumatic tool and stored inside the PTT torque meter.

Case Study

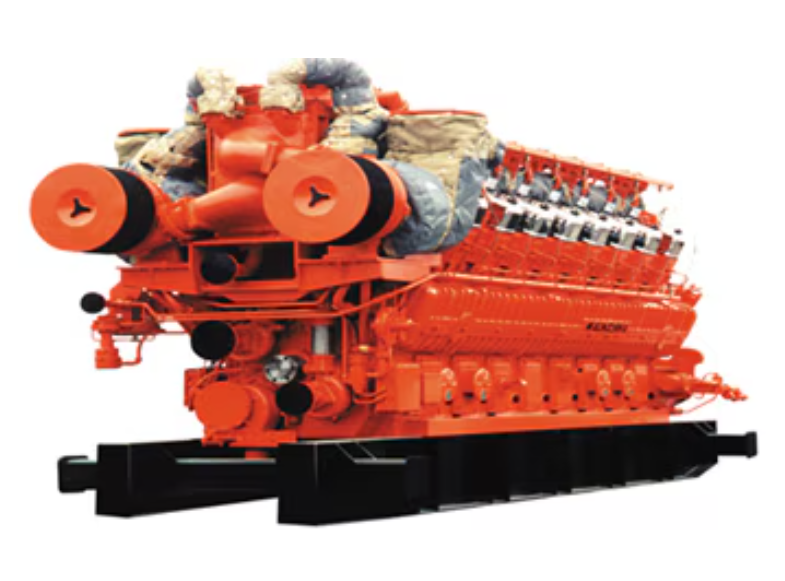

A manufacturer of large industrial gas engines had a torque application for fastening an industrial engine block in a washing chamber after the milling process. The large gas engines are designed and built for demanding applications in wastewater treatment plants, power plants, oil & gas fields and other energy applications all over the world.

Case Study

In large construction projects there are many factors that cause delays and unplanned expenses. Some are uncontrollable like weather. Other factors such as improper planning, lack of workers, or inadequate tooling are controllable.

Case Study

The Mountz torque multipliers were used in the maintenance process of opening and closing the two large valves daily. Over time, the plant manager saw the maintenance frequency and costs for servicing the tools decline.

Case Study

Looking to eliminate the lost production time and the cost of sending the torque tools out for calibration service, the manufacturer searches for a cost-effective method for in house calibration and documentation of calibration records for traceability.

Case Study

The Mountz Weld Stud Test Tool is designed for use during the production of sheet metal products to test the strength and integrity of welds used to attach threaded studs to the sheet metal.

Case Study

You don't want to be surprised by a torque wrench or screwdriver deemed "out of calibration". After all, torque tools are precision instruments used to tighten critical, often safety-sensitive fasteners.

Webinar

How do you select a torque wrench or screwdriver for a fastening application? Choosing a torque wrench or screwdriver for a torque application may seem straightforward. However, understanding the differences between tool types and product features can be confusing.

Webinar

In the intricate world of controlled manufacturing environments, where precision and cleanliness are paramount, the choice of tools plays a pivotal role. Dust, microbes, volatile organic compounds (VOCs), and pollutants are adversaries that must be meticulously managed in industries such as semiconductors, medical devices, aerospace and defense, and optics.

Webinar

Workplace injuries are a multi-billion dollar dilemma, especially for the manufacturing and production industry. The cost of preventing these injuries before they happen is always lower than the cost of dealing with injuries after they occur.

Webinar

Fumbling isn’t just a football occurrence. Assemblers fumble around with screws daily during the fastening process. The repetition of grabbing small fasteners from a bin is tedious and time-consuming. The constant repetition of picking up and fumbling around with hundreds and hundreds of screws daily is inefficient.

Webinar

Manufacturers experiencing excessive scrap-causing mistakes signal an assembly process control issue. How can engineers and quality teams actively work to reduce the amount of scrap generated from a poor fastening process?

Webinar

.jpg)

Assembly processes generate a vast amount of fastening data in real time that can provide valuable information to aid manufacturers in making more intelligent process decisions and minimizing quality failures while maximizing productivity.

Webinar

Did you know that an incorrect screw fastening sequence can provide unreliable results? The wrong sequence could cause manufacturing failures and add additional rework expenses. Joint relaxation occurs to some extent in all fastened joints and is a problem in joints where gaskets, or parts such as spring washers and plastics, are utilized.

Webinar

Controlling variables and eliminating manufacturing risks are essential enablers for efficient manufacturing. Detecting manufacturing irregularities early or preventing fastening failures is critical during production.

Webinar

Is your fastening process 100 % process safe? Or is it susceptible to torque failures or over-torque results? Using a vulnerable tool that provides erratic torque output or delivers frequent torque failures is a common sign that your quality management process has failed.

Webinar

If a product fails in the factory, it can be a costly nuisance. But if a screw rattles loose under field conditions, it can be dangerous, in the case of a missile guidance system, or deadly, in an internal medical device.

Webinar

Lack of torque control has caused wheel detachment on vehicles, failures with life-saving medical instruments, and prevented electronic devices from functioning. Without torque control, engineers risk product failures and escalating scrap rate costs with their manufacturing process.

Webinar

How do you know when a tool starts to drift out of calibration? Calibration drift is a quality issue that manufacturing engineers a nd quality engineers grapple with daily. Relying only on time-based calibration intervals for torque tools exposes manufacturers to risks. Over time and daily usage, torque tools will eventually deliver more or less torque than intended.

Webinar

Detecting and preventing manufacturing irregularities is essential to maintain a safe and efficient manufacturing process. One way to improve product outcomes is by using error-proofing techniques in your manufacturing process.

Webinar

Engineers can transform their fastening process through insights and intelligence powered by data integration and torque monitoring with a smart electric screwdriver system. Real-time torque data provides immediate fastening insights for manufacturers to monitor and improve processes, enabling manufacturing engineers to minimize operator errors and track a part's progress through the entire assembly process.

Webinar

Applying too much force while tightening a fastener can result in over-stretching a bolt, stripping a screw, breaking a screw head, or damaging the threads. Implementing a solution that prevents over-torque events is critical for engineers to reduce scrap rate costs. Applying the right amount of torque to each fastener maximizes its holding potential.

Webinar

Manufacturers should implement a fastening automation workflow process when there is a repetitive series of tightening tasks. Often these repetitive tasks are managed across multiple workstations, tools, and assembly operators. By creating a fastening automation workflow, the manufacturing process becomes streamlined and reduces human error risk. Workflow automation provides visibility of the various fastening tasks and improves production efficiency, consistency, and quality.

Webinar

Knowing how to measure dynamic torque can yield extremely valuable insight when troubleshooting joint application issues and evaluating power tool performance. Measuring torque on the joint in real-time can help manufacturers uncover and correct assembly inaccuracies before they cause serious quality product issues.

Webinar